Методичний посібник "Англійська мова за професійним спрямуванням. Матрос - моторист"

|

ДЕРЖАВНИЙ НАВЧАЛЬНИЙ ЗАКЛАД "ОДЕСЬКИЙ ПРОФЕСІЙНИЙ ЛІЦЕЙ МОРСЬКОГО ТРАНСПОРТУ"

МЕТОДИЧНИЙ ПОСІБНИК з предмету «Англійська мова за професійним спрямуванням»

Професія – Матрос, моторист Код – 8340.2 Кваліфікація – 2 класу

Викладачі англійської мови: Пашак Інна Валеріївна Гриценко Світлана Андріївна

Розглянуто на засіданні методичної комісії професій рядового плавскладу Протокол № ____ від ________ 2018 р.

Голова методичної комісії: _______________ Рачек О.В.

м. Одеса 2018р. |

Lesson 1

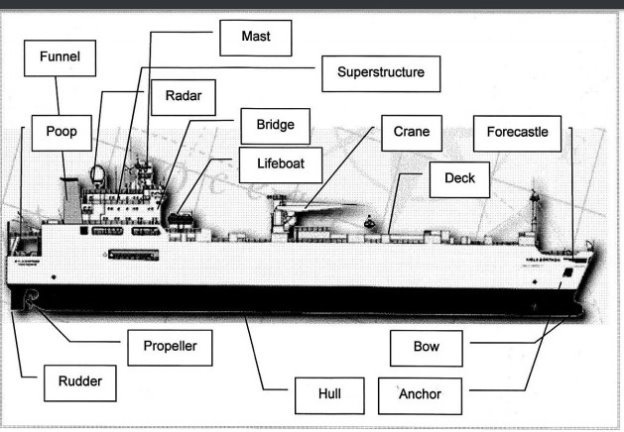

Ship’s architecture

hull – корпус (судна)

main deck – главная палуба

starboard (port) side –правый (левый) борт

bottom–дно, днище

frame–шпангоут, рамная конструкция

plating, skin–обшивка

keel – киль

watertight – водонепроницаемый

compartment – отсек

bulkhead – переборка – (стенки, разделяющие судно на отсеки).

cargo spaces–грузовые помещения

tween deck – твиндек, междупалубное пространство

engine-room – машинное отделение

tank–бак, цистерна

dry cargo ship – сухогрузное судно

hold – трюм

liquid cargo ship – жидко грузное судно

fore end – передняя (носовая) часть

forepeak – форпик (носовой отсек на судах, расположенный непосредственно у форштевня)

after end – кормовая (задняя) часть

after peak – ахтерпик (кормовая часть судна (продолжение киля) в виде рамы)

fuel – топливо

permanent housing – постоянные постройки

superstructure – надстройка

navigational bridge – навигационный (рулевой) мостик

funnel – труба

midship – мидель, середина судна

cofferdam – кофердам, перемычка (водонепроницаемая крепь)

inflammable – легко воспламеняющийся

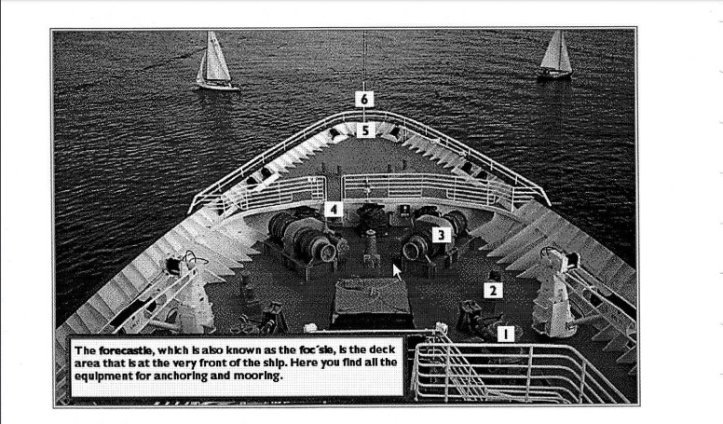

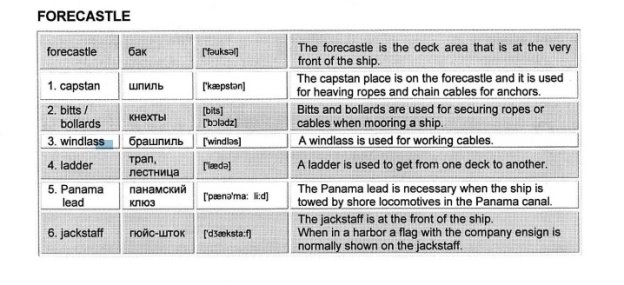

forecastle – баковая надстройка, бак

mooring – швартовка, швартовный

anchoring – якорный

equipment - оборудование

Ship’s Architecture

The main part of a ship is the hull. This is the area between the main deck, the sides – starboard side and the port side – and the bottom. It is made up of frames covered with plating, the keel joints them altogether. The hull is divided up into a number of watertight compartments by decks and bulkheads. Bulkheads are vertical steel walls going across the ship and alongside. Decks divide the hull horizontally. Those dividing up cargo spaces are known as “tween decks”. The hull contains the engine room, cargo space and a number of tanks. In dry cargo ships the cargo space is divided into holds, in liquid cargo ships it is divided into tanks. At the fore end of the hull are the forepeak tanks and at the after end are the afterpeak tanks. They are used for fresh water. The spaces between the holds and the bottom of the hull contains double bottom tanks. These are used for water ballast and fuel.

All permanent housing above the main deck is known as superstructure. For a traditional dry cargo ship main superstructure consisting navigational bridge and a funnel is placed on the midships, above the main deck. For modern ships the engine room and the main superstructure are situated at the after end of the ship to leave more space to load cargo. In tankers, between the engine room and the cargo hold there is a cofferdam, which protects inflammable cargoes from fire. At the fore end is the forecastle, where many of mooring and anchoring equipment are mounted.

1) Вопросы к тексту:

- What is the main part of a ship?

- What sides of the ship do you know?

- What is hull made up of?

- What is hull divided?

- What is the principal function of the bulkheads?

- What tween decks are used for?

- What is situated at the fore end?

- What is situated at the aft end?

- What are bottom tanks used for?

- What do we call permanent housing?

- Where is the navigational bridge and the funnel placed?

- Where is the engine room situated?

- What is cofferdam used for?

2) Закончите выражения.

- The main body of a ship is …

- The hull is divided up into a number of …

- Vertical steel walls going across the ship and alongside are called …

- Cargo spaces are also known as …

- Forepeak and afterpeak tanks are used for …

- Double bottom tanks are used for…

- Permanent housing above the main deck is known as …

- For modern ships the engine room is situated at the …

- In tankers, between the engine room and the cargo hold there is a …

Lesson 2

Vessel (general knowledge)

Перекладіть слова та вивчіть їх напам’ять

|

boat |

|

|

boiler-room |

|

|

bunk |

|

|

cabin |

|

|

cargo |

|

|

cargo-crane |

|

|

central control room |

|

|

cover |

|

|

derrick |

|

|

engine-room |

|

|

equipment |

|

|

galley |

|

|

gangway |

|

|

hatch |

|

|

hatch cover |

|

|

hold |

|

|

laundry |

|

|

main deck |

|

|

mess-room |

|

|

mooring gear |

|

|

mooring winch |

|

|

paint room |

|

|

porthole |

|

|

pump-room |

|

|

rope |

|

|

scupper |

|

|

sick-bay/hospital |

|

|

signal flags |

|

|

steering gear room |

|

|

stern |

|

|

store-room |

|

|

upper deck |

|

|

workshop |

|

|

Ship’s description |

|

|

area of sailing |

|

|

beam\width |

|

|

deadweight (DWT) |

|

|

draft\draught |

|

|

flag |

|

|

gross tonnage |

|

|

length overall |

|

|

Ship manager |

|

|

Ship owner |

|

|

speed |

|

|

type of vessel |

|

Lesson 3

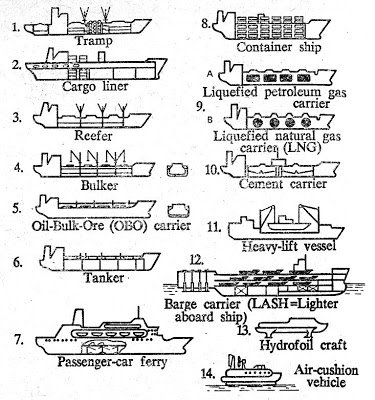

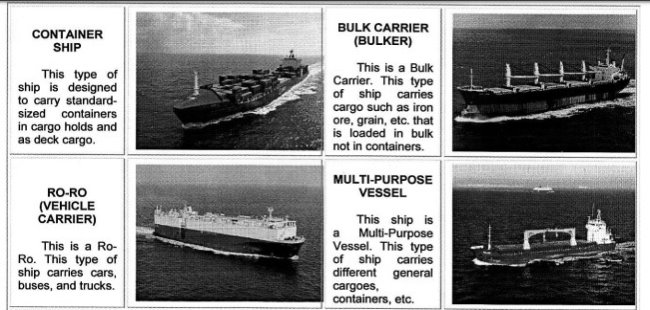

Types of Ships

-

Tramp - трамп

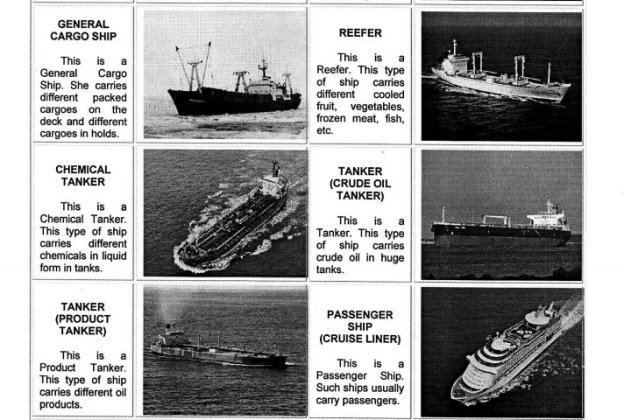

2. Cargo liner – грузовое судно

3. Reefer – рефрижераторное судно

4. Bulker - балкер

5. Oil-Bulk-Ore (ОBО) carrier – нефте - рудовоз

6. Tanker - танкер

7. Passenger-car ferry – авто-пассажирский паром

8. Containership - контейнеровоз

9. А. Liquefied petroleum gas carrier (LPG) – газовоз (сжиженный газ)

В.Liquefied natural gas carrier (LNG) – газовоз (природный газ)

10. Cement carrier - цементовоз

11. Heavy-lift vessel – тяжеловесное судно

12. Barge carrier (LASH=Lighter aboard ship) - баржевоз

13. Hydrofoil craft – судно на подводных крыльях

14. Air-cushion vehicle – судно на воздушной подушке

15. Ro-ro – ро-ро

16. Salvage ship – спасательное судно

17. Tug – буксир

18. Ice-breaker – ледокол

19. General purpose ship – грузовое судно (для общего груза)

20. Dry cargo vessel – сухогрузное судно

21. Dredger – экскаваторное судно

22. Timber-carrier - лесовоз

Прочитайте та перекладіть текст

There are many types of ships which operate over the seas. All liners carry passengers or cargo. They follow regular routes. Many ferry boats and container carriers operate as liners. Tramps do not sail on regular routes, they are employed where is the cargo for them to carry. A large number of merchant ships operate as specialized vessels, carrying particular types of cargo. Such as tankers carry oil; gas-carriers carry gas; ro-ro ships carry trailers and cars; timber-carrier carry timber. Reefer carries perishable cargo such as vegetables, meat and fruits. Bulkers are specially designed to transport unpackaged bulk cargo, such as grains, coal, ore, and cement in its cargo holds. An ore-bulk-oil carrier, also known as combination carrier or OBO, is a ship designed to be capable of carrying wet or dry cargoes. A heavy-lift ship is a vessel designed to move very large loads that cannot be handled by normal ships. They are of two types: semi-submerging vessels capable of lifting another ship out of the water and transporting it; and vessels that augment unloading facilities at inadequately equipped ports. The barge carriers (LASH) system refers to the practice of loading barges (lighters) aboard a larger vessel for transport. Lighters are typically towed or pushed around harbors, canals or rivers and cannot be relocated under their own power. Hydrofoil craft and Air-cushion vehicle are crafts capable of travelling over land, water, mud or ice and other surfaces. Salvage ship is the process of recovering a ship, its cargo, or other property after a shipwreck or other maritime casualty. A tugboat (tug) is a boat that maneuvers vessels by pushing or towing them. Tugs move vessels that either should not move themselves, such as ships in a crowded harbor or a narrow canal. An icebreaker is a special-purpose ship or boat that designed to move and navigate through ice-covered waters and provide safe waterways for other boats and ships. Dredger is used to excavate and remove material from the bottom of a body of water.

- Дайте відповіді на запитання:

- What types of special purpose ships do you know?

- Why are they called special purpose ships?

- What types of ships do tugs belong to?

- What does ro-ro carry?

- What do tankers carry?

- What does reefer carry?

- What does gas-carrier carry?

- How is cargo transported on board container ships?

- What ice-breakers are used for?

- What is the difference between bulkers and oil-bulk-ore carriers?

- How do tramps operate?

- What salvage ships are used for?

- Підберіть відповідний там вантажу (вид діяльності) до кожного типу судна.

- A tanker

- A reefer

- A salvage

- A tug

- An ice-breaker

- A passenger-liner

- A gas-carrier

- A fruit ship

- A ferry

- A barge carrier

- A general purpose ship

- A timber carrier

сarries gas;

gives assistance to the ships in distress;

carries perishable cargoes;

carries timber;

conducts ships through the ice;

carries passengers,

carries general cargo;

assists ships in entering and leaving ports;

carries barges;

carries oil;

carries passengers and cars;

carries fruits.

Lesson 4

Ship’s Crew

- Прочитайте та перекладіть текст

The man in charge of a ship is the Master. He is responsible for the ship, her cargo and the safety of the crew. He must be well-qualified and an experienced navigator. His correct title is the Master, but often he is addressed as “Captain”.

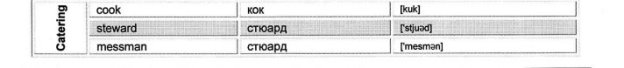

The crew of a cargo ship consists of Deck, Engine, Catering and Radio Departments. Each department is made up of officers, petty officers and ratings. At the head of every department is the most experienced officer. Master’s authority is supreme over all departments.

The Chief Officer (First Mate) is the Master’s first assistant and head of the Deck Department. He is assisted by a Second and Third Officers (Mates) and sometimes a Fourth Officer (Mate). The Deck Department also includes petty officers: a Boatswain (Bosun) and a Carpenter, and a number of ratings or non-licensed personnel of the Deck Department: Able-bodied Seamen (AB) and Ordinary Seamen (OS). These seamen compose the working crew of the deck force.

The Chief Engineer is head of the Engine Department. Engineers, electricians and engine room ratings are directly responsible to the Chief Engineer. On tankers there are also Pumpmen or Donkeymen.

The Catering Department and the Radio Department may consist of only one person each: the Ship’s Cook and Radio Officer. On board big passenger ships there are many stewards and cooks to serve passengers, and three radio officers for keeping continuous radio watch.

Ordinary Seamen work in all departments: deck, engineering and stewarding they

help with docking and undocking and sometimes stand watch. Most of the time Ordinary

Seamen maintain the vessel; chipping, scraping and painting. They also clean the

vessel’s interior and help in the galley.

Living conditions for Ordinary Seamen are different from ship to ship. On large

ships Ordinary Seamen have private rooms and share bathrooms. Smaller ships have

multiple berthing areas.

With experience an Ordinary Seaman can get promotion to Able Seaman

- Ответьте на вопросы к тексту:

- How many departments on board ships? What are they?

- Who is the Head of the Deck Department?

- Who is the Head of the Engine Department?

- Who keeps watch on the navigating bridge?

- Who keeps watch in the Radio-room?

- What are the Boatswain and the boatswain responsible for?

- What kind of man should be a Boatswain?

- What are the duties of the Ordinary Seaman?

- Who keeps watch in the engine-room?

- Why is it necessary to have skilled crew to operate a ship?

- Перекласти на англійську мову

Сучасне судно, складне обладнання, палубна служба, машинне відділення, бути відповідальним за, складатися з, бути готовим замінити капітана, нести вахту, заміняти один одного на вахті, висококваліфікований, підготовка екіпажу, визначити місцезнаходження судна, ремонтувати обладнання, брати пеленг, виконувати обов’язки.

- З’єднайте професію з обов’язками

the Master sailor responsible for food

the Chief Mate the safety of the ship, cargo and crew

the Second Mate the cargo

the Third Officer keeping watch in the engine-room

the Chief Engineer keeping the ship’s hull, holds, decks in good condition

the Radio Officer the crew’s work

the Boatswain keeping motors and generators in good condition

the Electricians the maintenance and repairs of the engine-room equipment

the motormen the radio-communication

the Cook navigational instruments and charts

Lesson 5

Duties of the Ordinary Seaman (OS) / Working day

My duties as an Ordinary Seaman are following:

At sea I must

- To keep a bridge lookout___________________________________________________

- To steer the ship__________________________________________________________

- To do general deck and bridge duties__________________________________________

- To scrub the deck_________________________________________________________

- To swab the deck_________________________________________________________

- To do paintworks_________________________________________________________

- To chip off the rust________________________________________________________

- To clean the holds and so on_________________________________________________

In the port I must

- To keep a deck watch______________________________________________________

- To assist with mooring operations____________________________________________

- To attend cargo operations__________________________________________________

- To fulfil the duties of the tallyman____________________________________________

- To control the fenders______________________________________________________

- To control that unauthorized person can not enter the ship____________________________________________________________________

- In case of need I must raise the alarm___________________________________________________________________

OS duties during cargo operations

- If the cargo is damaged I must give the command “stop loading!” and report to the OOW___________________________________________________________________

- I must not have any breaches of the discipline and obey the officers without any comments and discussions.______________________________________________________________

_______________________________________________________________________

- I must not consume alcohol and drugs_________________________________________

- I must always maintain my accommodation in a clean and tidy condition________________________________________________________________

__________________________________________________________________________

OS WORKING DAY

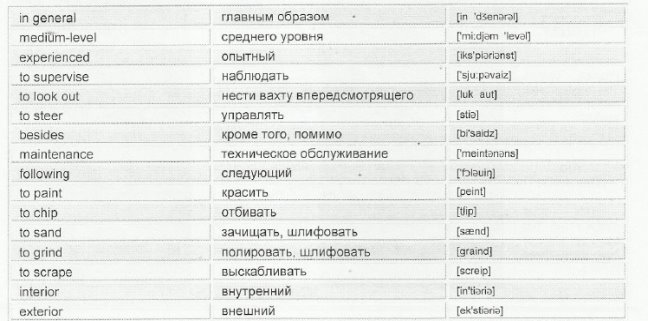

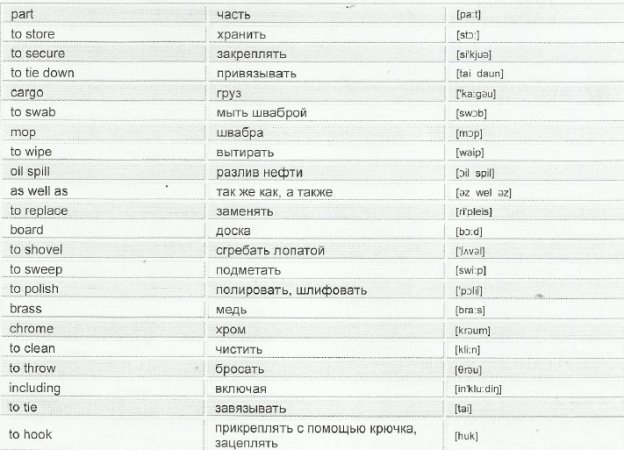

In general an Ordinary Seaman is working force crewmember onboard. Master, Chief Officer and a boatswain supervise him. The Ordinary Seaman keeps bridge watch, look outs and steers the ship. Besides, general vessel’s maintenance. The Ordinary Seaman is responsible to do the following:

- paint, chip, sand, grind and scrape the interior and exterior parts of the vessel.

- store, secure and tie down all cargo.

- swab decks with a mop.

- wipe oil spills as well as replace deck boards.

- shovel, sweep and clean materials out of holds.

- polish, brass and chrome as well as clean windows.

- throw lines, including tying and hooking lines to and from other vessels or structures.

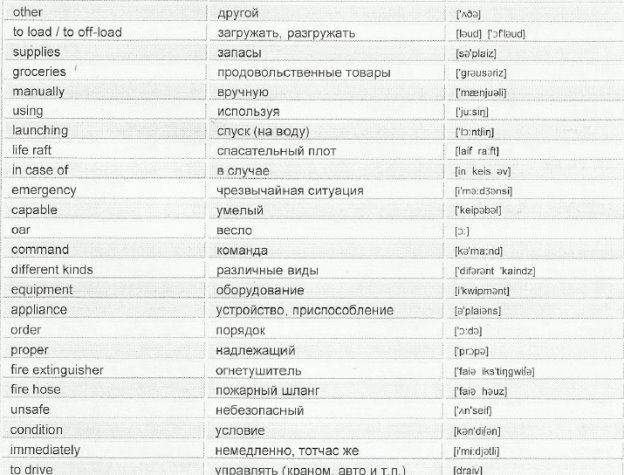

- load and unload supplies and groceries to and from the vessel manually or using a crane.

- be responsible for launching of life-boats and life-rafts in case of emergency.

- be capable of taking oar commands and operating different kinds of life-boats.

- be responsible for a life-boat and other ship’s equipment and appliances to be in good working order.

- understand proper use of fire extinguishers, fire hoses and life-rafts.

- report about any unsafe conditions to the Master or Chief Officer immediately.

- crane driving operations such as lifting cargo and equipment on or off the ship.

- gangway watch.

Vocabulary

Lesson 6

Watchkeeping

At the Gangway

When the ship is in the port the watchman keeps watch at the gangway. Не meets all the visitors and if necessary asks them to produce proper identification. He says, "Your identification, please". If he has any problems he must report them to the officer of the watch. He must lock all the doors leading to the superstructure and if necessary to store-rooms aft. Hе must keep the gangway area сlean.

He must inspect the aft mooring lines at regular intervals. And of course he must answer all the phone calls. In this case he says, "Hello, this is the m/v "A".

The gangway (or any other access to the vessel) shall be manned at all times, in compliance with the SSP (Ship Security Plan). Identification and recording of visitors, securing of all restricted spaces and other measures listed in the SSP, commensurate with the Security Level are to be strictly complied with. The applicable ‘MARSEC” level board is to be displayed at gangway.

The Chief Engineer should not commence any work that will make the Main engine or vital auxiliaries inoperative, without Master’s and Port authority’s permission.

A board displaying the vessel’s estimated departure time and cessation of shore leave should be placed near the gangway.

I. Translate the word combinations into English and use them in sentences of your own.

вахтовий помічник; нести вахту; мати проблеми; доповісти про проблему; замкнути двері; перевіряти швартові; дошка вахтової служби; знати, хто знаходиться на борту; не допускати сторонніх на борт

II. Learn the dialogue by heart.

DIALOGUE

|

A. |

- How do you do! I am the watchman. Can I help you? |

|

B. |

- I am a surveyor. I must check if the holds are ready for loading. Call the Chief Officer, please. |

|

A. |

- Just a minute. I`ll call him up. |

|

(to the Chief Officer over the telephone) |

- Chief, a surveyor is here to check if the holds are ready for loading. |

|

(to the surveyor) |

- The Chief Officer will be here in a minute. |

|

B. |

- Thank you. |

ON THE BRIDGE

If the ship is at sea sailors keeps watch on the navigating bridge. Usually there is the following navigational equipment on the bridge: a radar, a GPS receiver, a VHF, gyro and magnetic compasses, a course recorder, an echo sounder, a log. Also one can find many binoculars and a sextant on the bridge. There is a satellite station on the bridge too.

During the watch a seaman stands at the helm. If necessary he turns the helm to port or to starboard. He steers a steady course. He executes the wheel orders of the Master or the officer of the watch. If necessary a seaman takes bearings of landmarks. He also hoists flags or shapes in the day time and switches on the lights at night. A seaman must also look out for dangers.

The ship is under way. A seaman is on the bridge. He is keeping watch. I am standing at the helm. I am steering the ship. The ship is steady on course 230 degrees. He is keeping the course. The Master is standing near him. The officer of the watch is standing at the radar. The seaman is looking ahead. There is an on-coming vessel on my starboard. The Master is looking at her through the binoculars.

I. Learn the dialogues by heart.

DIALOGUE A

|

Watchman: |

186 on the gyrocompass, 188 on the magnetic compass. The auto-pilot is working. |

|

Officer of the watch: |

Fine. Take bearing of the ship on the starboard. |

|

Watchman: |

The bearing is 250 degrees. It is increasing slowly. |

|

Officer of the watch: |

O.K. Watch it closely.

|

DIALOGUE B

|

The officer of the watch: |

Port, steer one nine two. |

||||||||||||||

|

Watchman: |

Port steer one nine two... |

||||||||||||||

|

(later) |

Steady on one nine two. |

||||||||||||||

|

The officer of the watch: |

O. K. Steady so! |

||||||||||||||

|

(later) |

Steer on buoy № 1. |

||||||||||||||

|

Watchman: |

Steer on buoy № 1. |

||||||||||||||

|

(later) |

Steady on buoy № 1. |

||||||||||||||

|

The officer of the watch: |

Change over from manual to automatic control. |

||||||||||||||

|

Watchman: |

The auto-pilot is keeping, the course well. |

||||||||||||||

|

The officer of the watch: |

Finished with the wheel. Keep looking ahead. |

||||||||||||||

|

Watchman: |

Clear water ahead. |

||||||||||||||

|

The officer of the watch: |

O. K.

Wheel orders

|

||||||||||||||

|

|

Lesson 7

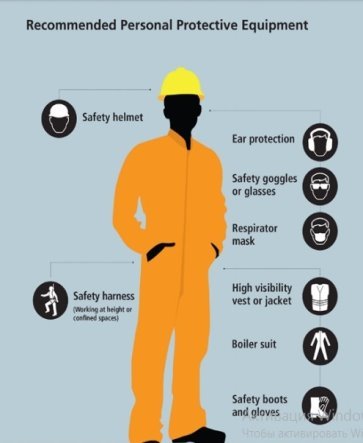

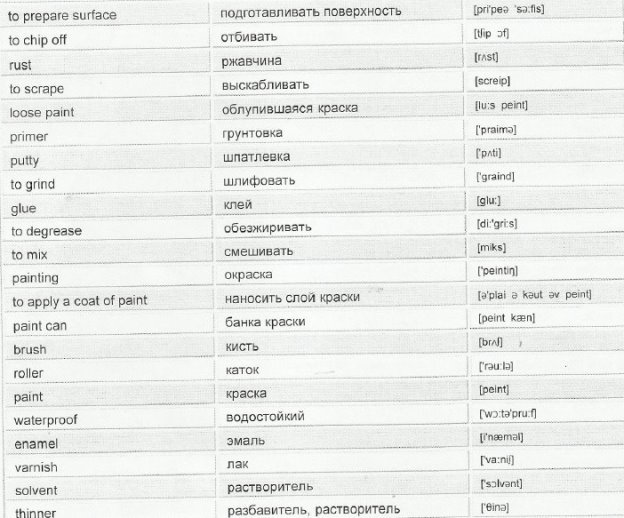

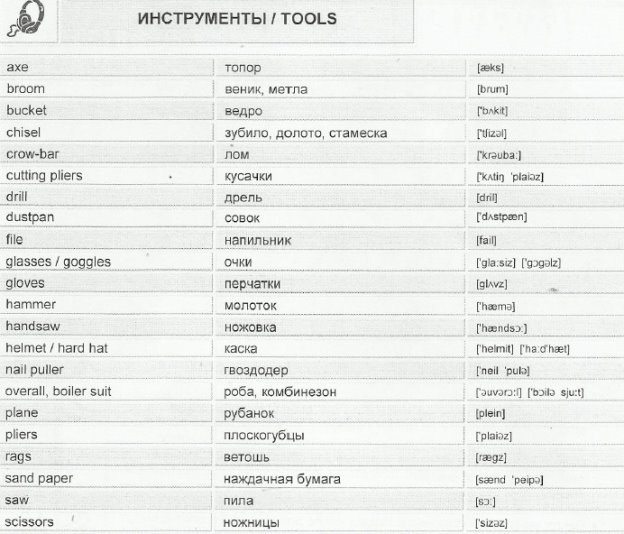

Painting / Tools

Painting / Tools

Прочитайте та вивчіть слова напам’ять

Vocabulary

.

Прочитайте та перекладіть діалог

Boatswain: You must start painting the ship's board. Chip off the rust with a chipping hammer. Then take one can with black paint and one can with white paint and start painting.

Sailor: Must I start painting from the bow to the stern?

Boatswain: Yes, you must. By the way, the paint is very thick and you must use the thinner. You can take the thinner, the paint and the paint-rollers in the paint locker.

Sailor: How many coats must I apply?

Boatswain: You must apply two coats of paint.

Lesson 8

Mooring

Mooring operations

Before start of mooring operation, the Master should consult with the Pilot about safe mooring in the port or harbor. When the ship wants to moor to the berth, the watchkeeping officer must order to slow the engines and go at a slow speed. Deck hands under Bosun’s supervision check that heaving lines, mooring ropes, fenders and anchors are ready for use.

Mooring is also controlled by the Third and Seconds Officers who gives orders from the poop and the forecastle. The Chief Officer controls all work from the bridge. He orders to stop the engines at some distance from the coast and to anchor the ship. Then all mooring lines are passed ashore and fixed at the bollards. After the ship is secured, rat-guards should be placed on all lines. A gangway watchman should regularly check all mooring lines.

The Master is responsible for ensuring that the vessel is correctly moored at all times when the vessel is on the pier or terminal. If the ship is well-moored, the vessel will remain in position in almost all kinds of the weather. When ropes are not in use they should be stowed under deck in a well-ventilated room. Do not store them close to the boiler-rooms or other hot areas. Ropes should be visually inspected at regular intervals externally and internally. If there is any damage or excessive wear the lines should be replaced.

The winch brake is the heart of the mooring system as it secures the drum and the mooring line. The brake is the safety device if the load becomes excessive. The brake of the mooring winches must be tested regularly.

Always ensure there is enough personnel on duty (and on deck) to handle the operation and maintain the ship in safe condition. If mooring must be secured on bitts at least three men are required at the mooring station. If moorings are winch reeled, two men should be enough.

Mooring lines

|

Mooring line |

Швартовый конец |

|

Heaving line |

Бросательный |

|

Head line |

Носовой продольный |

|

Stern line |

Кормовой продольный |

|

Breast line |

Прижимной |

|

Spring |

Шпринг |

|

Forward (bow) spring |

Носовой |

|

Aft (stern) spring |

Кормовой |

Mooring orders

|

Stand-by-mooring! |

|

|

Have heaving lines ready forward and aft! |

|

|

Take the towing line! |

|

|

Heave breast line! |

|

|

Stop heaving! |

|

|

Fix breast line! |

|

|

Make fast stern line! |

|

|

Let go all lines! |

|

|

Slack away the forward spring! |

|

|

Pick up the slack on the aft breast line! |

|

Mooring rules

DO NOT stand to close to a winch drum or bitt when holding a line under tension; hold a line about 1 meter away from the drum or bitt.

DO NOT apply too many turns; generally it is enough to have 5 turns

DO NOT stand close to a rope under load; it may part without warning

DO NOT have more people than necessary in the vicinity of a line

DO NOT hold a line in position by standing on it

DO NOT leave winches and windlasses running unattended

DO NOT use dangerously warn lines

DO wear safety hat

DO wear gloves when handling wires. However gloves can be dangerous when handling a rope on the drum end and should not be warn.

DO keep a sharp knife and a flashlight for night operations. There must be good communication before starting operations. Only experienced persons can operate winches.

Lesson 9

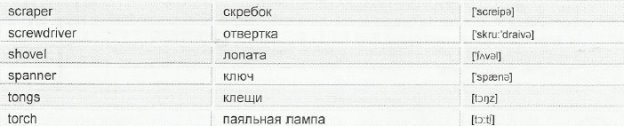

Signal flags/Tools

International Code Flags

The International Code of Signals (ICS) comprises forty special flags, which enable any vessel and Shore Signal Stations to send and receive messages. The stowage of Code Flags for easy use must be correct. Usually they are stowed in a Flag Locker. This is a wooden box with small square holes – called pigeon holes – in which each Code Flag is stowed separately, with the letter A, B, C, D etc., marked clearly under each compartment. Watchman can quickly or easily find any flag to compose a message of one-, two- or three- letters, according to ICS Coding book. Experienced seamen know the most important signals by heart. Here are some of them:

Single-Letter Signals:

B – Bravo – I am taking in, or discharging, or carrying dangerous goods.

D - Delta – Keep clear of me; I am maneuvering with difficulty.

K – Kilo – I wish to communicate with you.

L – Lima – You should stop your vessel instantly.

O – Oscar – Man overboard.

P – Papa – All persons should report onboard as the vessel is about to proceed to sea.

Q – Quebec – My vessel is “healthy” and I request free pratique.

U – Uniform – You are running into danger.

V – Victor – I require assistance.

Two-Letter Signals:

NC – | November-Charlie | I am in distress and require immediate assistance.

A large set of three letter signals beginning with M contains information on Medical Section need for a medical assistance, when a doctor on board is not available.

ICS signals may be transmitted not only by flags but also by radio in Morse Code or in voice, or by a flashing light in Morse Code, or even by hand semaphore. When transmitting by voice, every letter or figure is called according to the Phonetic Alphabet and Figure Code, to avoid any mistake in the transmitted message. So, the letter A is called “Alfa”, E – “Echo”, F – “Foxtrot”, G – “Golf”, H – “Hotel”, and so on. Thus no letter can be confused with any other.

|

A – Alfa – diver down. Keep well clear at slow speed. |

Я спустил водолаза, соблюдай дистанцию и проходи на малой скорости. |

|

B – Bravo – taking in, discharging or carrying dangerous goods. |

Я гружу (выгружаю/имею) на борту опасный груз. |

|

C – Charlie – yes (affirmative) |

Да (утвердительный) |

|

D – Delta – keep clear, I am maneuvering with difficulty. |

Держитесь в стороне от меня, я маневрирую с трудом. |

|

E – Echo – I am altering my course to Starboard. |

Я изменяю свой курс вправо. |

|

F – Foxtrot – I am disabled. Communicate with me. |

Я не управляюсь, держите со мной связь. |

|

G – Golf – I require a pilot. |

Мне нужен лоцман. |

|

H – Hotel – I have a pilot onboard. |

У меня на борту лоцман. |

|

I – India – I am altering my course to Port. |

Я изменяю свой курс влево. |

|

J – Juliett – I am on fire. Dangerous cargo. Keep well clear. |

У меня опасный груз на борту. |

|

K – Kilo – I wish to communicate with you. |

Я хочу установить с вами связь. |

|

L – Lima – You should stop your vessel instantly |

Остановите немедленно свое судно. |

|

M – Mike – My vessel is stopped. |

Мое судно остановлено и не имеет хода относительно воды. |

|

N – November – No, (negative) |

Нет (отрицательный) |

|

O – Oscar – man overboard |

Человек за бортом |

|

P – Papa – Recall. All persons required onboard. Vessel about to sail. |

Все должны быть на борту, т.к. судно скоро снимается. |

|

Q – Quebec – Vessel is healthy. Request free practique |

Мое судно незараженное, прошу предоставить мне свободную практику. |

|

R – Romeo – Ready duty ship |

Принято, я принял ваш последний сигнал. |

|

S – Sierra – My engines are going full speed astern. |

Мои машины работают на задний ход. |

|

T – Tango – Keep clear of me, I am engaged in pair trawling. |

Держитесь в стороне от меня, я произвожу парное траление. |

|

U – Uniform – You are running into danger. |

Вы идете к опасности. |

|

V – Victor – I require assistance. |

Мне требуется помощь. |

|

W- Whiskey – I require medical assistance |

Мне требуется медицинская помощь. |

|

X – X-ray – Stop carrying out your intensions & watch for my signals. |

Приостановите выполнение ваших намерений и наблюдайте за моими сигналами. |

|

Y – Yankee – I am dragging my anchor. |

Меня дрейфует на якоре. |

|

Z – Zulu – I require a tug. |

Мне требуется буксирное судно |

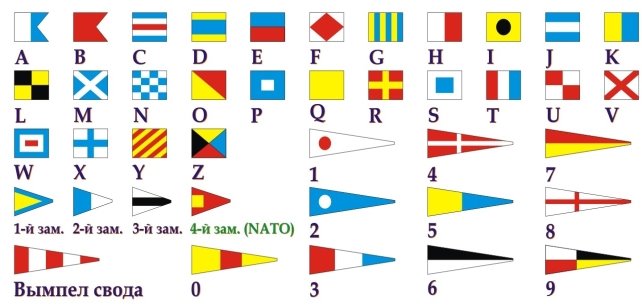

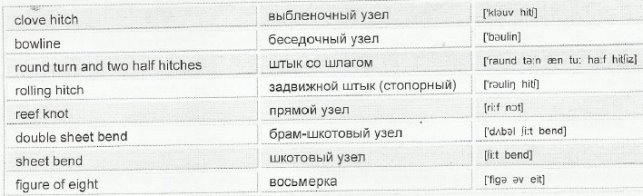

Seaman’s knots

Seamen’s Knots

A few knots known and used correctly and promptly show a better seaman that one who knows all the names of the lesser used knots but who is slow or inaccurate in their execution. The simplest round turn can be a big help when used properly. In an emergency a quick turn round some strong object on board will frequently prevent accident or damage. Every knot has its own use in good seamanship:

- to make a loop in the end of a rope without splicing – a Bowline

- for securing a rope at intermediate points – a Clove Hitch

- to prevent a rope from slipping – a Rolling Hitch

- when making a rope fast to the bight of another – a Sheet Band, and so on.

Lesson 10

DUTIES IN EMERGENCY SITUATIONS

General emergency alarm

Alarm signal: seven (7) short blasts (or more) and one (1) long blast on ship's whistle and continuous sounding of ship's general ALARM.

When General Alarm sounds it does not necessarily means to Abandon Ship.

At the general emergency alarm the sailor must:

1. close the watertight doors, leading to the superstructure and other compartments;

2. get ready the life-boats for launching;

3. get ready the life-saving equipment.

If an able seaman is second in command of the damage control party he must get ready the portable firefighting appliances.

The crew on watch must remain in their positions on signal for Emergency Drill.

Fire alarm

Fire signal: groups of rapid rings for a period of 10 seconds on ship's bell and the same on ship's general alarm (electric).

Person discovering fire should immediately notify the bridge and fight the fire with available equipment until the Emergency Squad arrives.

In case of fire the sailor must:

1. break the glass of the fire-alarm box and press the button;

2. call up the bridge and inform the officer of the watch;

3. close the watertight doors, fire doors;

4. evacuate people if necessary;

5. bring the fire-crowbar, the fire-axe, sand and hoses to the seat of the fire;

6. bring the hand fire nozzle to the seat of the fire and operate it;

7. put out the fire with an extinguisher.

A sailor may also act as a messenger.

Immediately upon the fire emergency signal, fire pumps to be started, all watertight doors should be closed, and all fans and blowers to be stopped. Fire hoses to be led immediately out in the affected area as directed.

Flooding

Flooding signal: three long rings on general alarm bells.

In case of flooding the sailor must:

1. bring the collision mat and the sheets and make fast the collision mat;

2. stand by the control lanyard;

3. bring and make fast the hogging line;

4. stand by the winch;

5. if necessary, stop the hole with a cement box and sand, and liquid glass from the inner side.

Man overboard

Alarm signal: Immediately hail and pass to the bridge "Man overboard".

Upon hearing the signal "Man overboard" life rings, buoys must be thrown immediately into the sea, engines must be stopped, and lookout aloft must be sent.

Emergency Boat crew consisting of all seamen should immediately clear lee boat for launching.

At the "man overboard" alarm the sailor must:

1. screw the drain plug;

2. carry the painters;

3. bring the blankets;

4. release the boat gripe;

5. release the life-boat falls;

6. heave in the painters;

7. launch the life-boat;

8. act as a rower.

Boat alarm

Signals:

Commencing lowering: One(1) short blast on whistle

Stop lowering: Two (2) short blasts on whistle

At the boat alarm the sailor must:

1. screw the drain plugs;

2. release the boat gripe;

3. get ready the painters;

4. release the forward (aft) life-boat falls;

5. throw the life-rafts overboard;

6. ensure safe embarkation of the life-boats and rafts;

7. act as a helmsman.

Lifeboat Launching Procedure

1. uncover the lifeboat;

2. remove harbor pins;

3. release gripes, keel block fastening, boat davit stoppers;

4. screw the drain plug;

5. release hand-rail

6. lower the embarkation ladder;

7. check the life-boat supplies (fresh water, survival pack, blankets).

I. Answer the questions.

1. What doors must the sailor close at the general emergency alarm?

2. What must the sailor bring to the seat of fire?

3. How can the sailor stop a hole?

4, When must the sailor screw the drain plug before or after launching a life-boat?

5. When must people (люди) take to (садиться) life-boats to ensure safe embarkation?

6. Where must you go

a) at the general emergency alarm;

b) at the fire alarm;

c) in case of flooding;

d) at the boat alarm;

e) at the "Man overboard" alarm.

Part II

Lesson 11.

Engine Room: General Information

Marine propulsion is the mechanism or system used to generate thrust to move a ship or boat across water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of a motor or engine turning a propeller, or less frequently, in jet drives, an impeller. Marine engineering is the discipline concerned with the design of marine propulsion systems.

Steam engines were the first mechanical engines used in marine propulsion, but have mostly been replaced by two-stroke or four-stroke diesel engines, outboard motors, and gas turbine engines on faster ships. Nuclear reactors producing steam are used to propel warships and icebreakers. Electric motors have been used on submarines and electric boats and have been proposed for energy-efficient propulsion. Recent development in liquefied natural gas (LNG) fuelled engines are gaining recognition for their low emissions and cost advantages.

On a ship, the engine room is the propulsion machinery spaces of the vessel. The engine room is generally the largest physical compartment of the machinery space. The engine room houses the vessel’s prime mover – diesel engine, gas or steam turbine. On some ships, the machinery space may comprise more than one engine room, such as a forward and aft, or port or starboard engine rooms, or may be simple numbered.

On a large number of vessels, ships and boats, the engine room is located near the bottom and at the aft end of the vessel, and usually comprises few compartments. The engine room on some ships may be situated mid-ship. With the increased use of diesel electric propulsion packages, the engine room may be located well forward, low or high on the vessel, depending on the vessel use.

The engine room of a motor vessel typically contains several engines for different purposes. Main or propulsion engines are used to turn the ship’s propeller and move the ship through the water. They typically burn diesel oil or heavy fuel oil, and may be able to switch between the two.

Large engines drive electrical generators that provide power for the ship’s electrical systems. Large ships typically have three or more synchronized generators to ensure smooth operation.

On a steamship, power for both electricity and propulsion is provided by one or more large boilers. High pressure steam from the boiler is used to drive engines: reciprocating engines or turbines for propulsion, and turbo generators for electricity. Besides propulsion and auxiliary engines, a typical engine room contains many smaller engines, including generators, air compressors, feed pumps, and fuel pumps.

II. Find in the text English equivalents for the following word combinations.

Морське машинобудування, механічні системи, були замінені, забезпечують живлення, більш швидкі судна, енерго-ефективні двигуни, низький рівень викидів і цінові переваги, розташовується (2 варіанти), використання судна, різні цілі, електричні системи, великі котли.

III. Translate into Ukrainian.

1. Marine propulsion is the mechanism or system used to generate thrust to move a ship or boat across water.

2. Marine engineering is the discipline concerned with the design of marine propulsion systems.

3. Steam engines were the first mechanical engines used in marine propulsion.

4. Nuclear reactors are used to propel warships and icebreakers.

5. The engine room is the propulsion machinery spaces of the vessel.

6. The engine room is generally the largest physical compartment of the machinery space.

7. The engine room houses the vessel’s prime mover – diesel engine, gas or steam turbine.

8. Main or propulsion engines typically burn diesel oil or heavy fuel oil.

9. Large ships typically have three or more synchronized generators to ensure smooth operation.

10. Besides propulsion and auxiliary engines, a typical engine room contains many smaller engines, including generators, air compressors, feed pumps, and fuel pumps.

Lesson 12.

THE ENGINE DEPARTMENT

The Chief Engineer, or Chief Engineering Officer, is in charge of the Engine Department. He is responsible for all technical operations of the vessel, including engineering, electrical and mechanical units. In particular, he is responsible for all the propulsion machinery, power generating equipment and auxiliaries. He has to keep documents on the machinery working as well as all the repairs carried out on the vessel. He also logs fuel oil consumption. A varying number of officers, petty officers and ratings assist the Chief Engineer. The engine officers’ hierarchy goes as follows:

1) The First Engineer. He is responsible for maintenance and operations of the engineering and technical units.

2) The Second Engineer. His responsibilities usually include the maintenance of lubricating systems, engine room auxiliaries, and electrical equipment.

3) The Third Engineer. He is usually responsible for fuel and water systems. He also supervises tanks soundings and monitors the boiler room equipment.

4) The Fourth Engineer. His responsibilities may include, for instance, the operation and maintenance of engine room auxiliaries.

5) The Motorman. His duties are defined by the Head of the Engine Department and can include, for example, the daily maintenance and cleaning of specific engine parts.

The propulsion plant department can also include some petty officers, such as the donkey man and the storekeeper and, if the ship is a tanker, there may also be the pump man. The first one mentioned attends a donkey, auxiliary boiler, especially when the ship is in port. A storekeeper is in charge of all the spare parts and equipment stored for the engine room. The last one, a pump man, is employed to maintain and operate cargo pumps.

The engine room ratings, e.g. fire-fighters, greasers are usually employed on watches to assist the engineer in charge. They are responsible for daily cleanliness of the engine room and for routine oiling, greasing and machinery servicing.

The machinery driving a vessel which is underway is usually operated 24 hours a day. All running machinery must be controlled continuously in order to prevent any failure of the equipment. The majority of control systems on modern ships are automatic. A ship may operate for agreed periods with unmanned machinery, called UMS, which stands for Unattended Machinery Spaces.

The standard system of watches adopted on board is usually a four-hour period on duty followed by eight-hour rest. The word “watch” means both the period and the crew working at that time. The three watches in any 12 hour period are usually: 12 to 4, 4 to 8, 8 to 12. Thus, for instance, an engineer on duty for the 8 to 12 watch works from 8 a.m. to 12 noon and from 8 p.m. to 12 midnight.

A watch is usually made up of an engineer in charge with an assistant engineer and a rating. Their duties include inspecting the main propulsion plant, auxiliary machinery

1. Complete the sentences. Translate.

1. The Chief Engineer, or Chief Engineering Officer, is ___.

2. He is responsible for all technical operations of the vessel, including ___.

3. In particular, he is responsible for all the propulsion machinery, ___.

4. He has to keep documents on the machinery working as well as all the ___.

5. He also keeps the log records of ___.

6. A varying number of ___ assist the Chief Engineer.

II. Complete the sentences.

A The Chief Engineer, or Chief Engineering Officer, is in (1) ___ of the Engine Department. He is responsible for all technical operations of the (2) ____, including engineering, electrical and mechanical units. In particular, he is responsible for all the (3) ___ machinery, power generating equipment and (4) ___. He has to keep documents on the machinery working as well as all the (5) ___ carried out on the vessel. He also logs fuel oil consumption. A varying number of officers, petty officers and (6) ___ assist the chief engineer.

B The engine officers’ hierarchy goes as follows:

1) The First Engineer. He is responsible for (1) ___ and operations of the engineering and technical units.

2) The (2) ___ Engineer. His responsibilities usually include the maintenance of (3) ___ systems, engine room auxiliaries, and electrical equipment.

3) The Third Engineer. He is usually responsible for fuel and water systems. He also supervises tanks (4) ___ and monitors the boiler room equipment.

4) The Fourth Engineer. His responsibilities may include, for instance, the operation and maintenance of engine room (5) ___.

5) The Motorman. His duties are defined by the (6) ___ of the Engine Department and can include, for example, the daily (7) ___ and cleaning of specific engine parts.

III. Match the jobs and the duties

|

1 |

The Second Engineer. |

a |

He is responsible for maintenance and operations of the engineering and technical units. |

|

2 |

The Fourth Engineer. |

b |

His responsibilities usually include the maintenance of lubricating systems, engine room auxiliaries, and electrical equipment. |

|

3 |

The First Engineer. |

c |

He is usually responsible for fuel and water systems. He also supervises tanks soundings and monitors the boiler room equipment. |

|

4 |

The Third Engineer. |

d |

His responsibilities may include, for instance, the operation and maintenance of engine room auxiliaries. |

IV. Insert the missing terms

The propulsion plant department can also include some (1) ___ officers, such as the (2) ___ and the storekeeper and, if the ship is a tanker, there may also be the (3) ___. The first one mentioned attends a (4) ___, auxiliary boiler, especially when the ship is in port. A (5) ___ is in charge of all the spare parts and equipment stored for the engine room. The last one, a (6) ___, is employed to maintain and operate cargo pumps.

The Motorman's duties are defined by the head of the engine department and can include, for example, the (7) ___ and cleaning of specific engine parts. The engine room (8) ___, e.g. fire-fighters, (9) ___ are usually employed on watches to assist the engineer in charge. They are responsible for daily cleanliness of the engine room and for routine (10) ___ greasing and machinery servicing.

V. Answer the questions.

What is the Chief Engineer in charge of?

What is he responsible for?

What is he responsible for in particular?

What kind of documents must he keep?

What must he log?

Who assists the Chief Engineer?

VI. Choose the appropriate term

The standard system of watches adopted on board is usually a two/three/four-hour period on duty followed by eight-hour rest.

The word “hour/watch/guard” means both the period and the crew working at that time.

The two/three/four watches in any 12 hour period are usually: 12 to 4, 4 to 8, 8 to 12.

Thus, for instance, an engineer on job/duty/work for the 8 to 12 watch works from 8 a.m. to 12 noon and from 8 p.m. to 12 midnight.

A watch is usually made up of an engineer in cargo/charge/job with an assistant engineer and a mate/rating/greaser.

Their duties include inspecting the main propulsion plant, auxiliary machinery and starting/stearing/steering gear spaces.

They should note any malfunctions and stoppages/defects/breakdowns, report and correct them.

Lesson 13.

Engine Orders

IMO STANDARD MARINE COMMUNICATION PHRASES (SMCP 2001)

IV-A/2 - STANDARD ENGINE ORDERS

Any engine order given should be repeated by the person operating the bridge telegraph(s) and the officer of the watch should ensure the order is carried out correctly and immediately.

ORDERS:

1. Full ahead – повний вперед

2. Half ahead – середній вперед

3. Slow ahead – малий вперед

4. Dead slow ahead – найменший вперед

5. Stop engine(s) – стоп машина

6. Dead slow astern – найменший назад

7. Slow astern – малий назад

8. Half astern – середній назад

9. Full astern – повний назад

10. Emergency full ahead – аварійний повний вперед

11. Emergency full astern – аварійний повний назад

12. Stand by engine – приготовути машину (engine-room personnel fully ready to manoeuvre and bridge manned to relay engine orders)

13. Finished with engine(s) – машина більше не потрібна (movement of engine(s) no longer required).

In vessels fitted with twin propellers, the word "both" should be added to all orders affecting both shafts, e.g. "Full ahead both" – обидві машини повнийвперед, and "Slow astern both" – обидві машини малий назад, except that the words "Stop all engines" – стоп обидві машини should be used, when appropriate. When required to manoeuvre twin propellers independently, this should be indicated, i.e. "Full ahead starboard" – права повний вперед, "Half astern port" – ліва середній назад, etc.

Where thrusters are used, the following orders are used:

14. Bow thrust full/half to port side – носове підрулююче повний/середній вліво

15. Bow thrust full/half to starboard side – носове підрулююче повний/середній вправо

16. Stern thrust full/half to port side – кормове підрулююче повний/середній вліво

17. Stern thrust full/half to starboard side – кормове підрулююче повний/середній вправо

18. Bow/stern thrust stop – носове/кормове підрулююче стоп

Lesson 14.

DIESEL ENGINE

The diesel engine is an internal combustion engine which ignites the fuel by injecting it into high hot pressure air in a combustion chamber. The diesel engine has either a four-stroke or a two-stroke cycle. A stroke is a travel of the piston between its extreme points.

The four stroke cycle consists of inlet (or suction), compression, power (or working stroke) and exhaust. This cycle is completed in two revolutions of the crankshaft. At the top dead centre (TDC) the inlet valve opens and fresh air is drawn in as the piston moves down – suction stroke. At the bottom dead centre (BDC) the inlet valve closes and the air in the cylinder is compressed as the piston rises – compression. Fuel is injected as the piston reaches top dead centre and combustion takes place producing very high pressure in the gases. There gases force the piston down and at bottom dead centre the exhaust valve opens. The final stroke is the exhausting of the burnt gases as the piston rises to top dead centre.

The two-stroke cycle is completed in the two strokes of the piston during one revolution of the crankshaft: the upstroke (scavenge and compression) and the downstroke (power and exhaust stroke). Instead of valves holes known as “ports” are used which are opened and closed by the sides of the piston as it moves. When the piston is forced down on its working stroke it uncovers (opens) the exhaust ports. The burnt gases then begin to exhaust and the piston continues down until it opens the inlet or scavenge ports. Pressurized air then enters and drives out the remaining exhaust gases. The piston on its return stroke closes the inlet and exhaust ports. The air is then compressed as the piston moves to the top of its stroke.

I. Complete the sentences.

1. The diesel engine has either ___.

2. At the top dead center the inlet valve opens and ___.

3. A stroke is ___.

4. There gases force the piston down and ___.

5. The two-stroke cycle is completed in ___.

II. Answer the questions.

1. What is a diesel engine?

2. What cycle does a diesel engine have?

3. What does the four-stroke cycle consist of?

4. When is the air in the cylinder compressed?

5. What is the final stroke of the four-stroke cycle?

6. What is used instead of valves in the two-stroke diesel engines?

7. When are the exhaust ports uncovered?

8. When are the exhaust ports closed?

Lesson 15.

TWO-STROKE AND FOUR-STROKE DIESEL ENGINES

Any internal combustion engine, regardless of principle it operates on, has a four-stroke or a two-stroke cycle. All modern diesel engines are single-acting, i.e. there is only one combustion space, above the piston. The double-acting principle, i.e. with a combustion space both above and below the piston, was also popular for many marine engines. But engines employing this system are now obsolete because of their relatively complex design and difficulties in maintenance.

The four-stroke cycle consists of the suction stroke, compression stroke, combustion and expansion stroke, and exhaust stroke. The piston starts downward, suction stroke. The air inlet valve is open and air is drawn into the cylinder through the air inlet pipe. The exhaust valve, fuel valve are all closed. As the piston reaches the end of the suction stroke the air inlet valve closes and as the piston rises on the second, compression stroke, the air in the: cylinder is compressed to about 480 pounds and its temperature rises to about 1.000 F. The fuel injection valve now opens and the fuel oil is sprayed into the cylinder under a pressure of 3.550 p.s.i. The high temperature of the compressed air in the cylinder ignites the fuel, and it continues to burn as long as injection is maintained. The pressure in the cylinder, increases and the piston is driven downwards. This is the third, power stroke. The injection valve closes shortly after the piston has started down on this stroke. At the end of this stroke the exhaust valve opens and the burned gases in the cylinder, now reduced to 40 pounds pressure, start to flow out through the exhaust pipe. Returning on the fourth, exhaust stroke, the piston pushes the remaining gas out of the cylinder, through mechanically operated exhaust valves. The complete cycle of operation thus requires four stokes of the piston, and in each cylinder there is one power stroke during two revolutions of the crankshaft.

In the two-stroke engine the complete cycle of operation takes place during one revolution of the crankshaft:

1) the up stroke, the scavenge and compression stroke

2) the down stroke of the piston being, the power and exhaust stroke.

Instead of an exhaust valve there is ring of exhaust ports around the bottom of the cylinder, communicating with the exhaust pipe. In place of air inlet valves there are scavenging ports. When the piston on its downward stroke uncovers the exhaust ports, and the cylinder pressure drops to atmospheric, they open and the air under pressure flows into the cylinder and pushes the exhaust gases out through these ports. As the piston on its up-stroke covers the scavenging ports, the exhaust ports close, leaving the cylinder full of fresh air. Just before the end of the compression stroke, fuel is injected. As it burns, and the gases expand within the combustion chamber, the piston is driven down on its power stroke. Although with the two-stroke engine there are twice as many power strokes per revolution as in the four-stroke engine, the power developed is not doubled by using the two-stroke cycle. Power is absorbed in pumping losses. Moreover, the power stroke is partly lost for exhaust and scavenging. The diesel engines may also be opposed piston type, crosshead type and trunk piston type. Large diesel engines, which have cylinder near 900 mm in diameter turn at the relatively slow speed at about 145 rpm and less. They are known as slow speed diesel engines. At this low speed the engine requires no reduction gearbox between it and the propeller. Medium speed diesel engines operate between 150 and 450 rpm, therefore they are connected to the propeller by gearing.

I. Read the text and translate the following sentences into English.

1. Всі сучасні дизельні двигуни – це двигуни простоїдії.

2. У двигунів простого дії всього одна камера згоряння.

3. Дизельні двигуни також можуть бути двигунами з протилежнорухомими поршнями, крейцкопфними двигунами, тронковими двигунами.

4. Великі дизельні двигуни обертаються на низькій швидкості.

5. Низькооборотні двигуни зазвичай мають циліндр діаметром 900 мм.

6. У низькооборотних двигунів немає понижуючого редуктора.

7. Середньооборотні двигуни працюють на швидкості 150-450 оборотів в хвилину (rpm – revolutions per minute).

8. Середньооборотні двигуни з'єднані з гвинтом зубчастою передачею.

9. Чотиритактні суднові дизелі поділяються на головні і допоміжні.

10. Головні дизелі є джерелами енергії для приводу рушіїв.

11. Допоміжні дизелі виробляють енергію для роботи електричних генераторів, компресорів та інших механізмів.

Lesson 16.

LUBRICATING OIL SYSTEMS

It is important that not only that the proper type of lubricant is used, but also that the lubricant is supplied to the sliding or rolling parts in proper quantities, at the proper temperature, and that provisions be made to remove any impurities which enter the system. The engine lubricating systems are designed to fulfill these requirements, as the life and reliability of the engine depend on good lubrication.

Most conventional marine diesel engines use three separate lubricating systems. They are the following: (I) the crankcase oil with its pump, filter and cooler used for the crankshaft, connecting rod and camshaft bearings, and for piston cooling; (2) the cylinder oil and the cylinder lubricators adjusted to meter a specific number of drops per minute; (3) the valve-gear centralized lubricating system in which lubricant is drained separately in order to prevent contamination of the crankcase oil by leaking fuel, injector cooling water, or exhaust gas.

2-cycle and 4-cycle diesel engines are supplied with lubricating oil under pressure to all bearings and moving parts. Therefore, such systems are called pressure-lubricating systems whose essential parts are the following: (I) Tanks and sumps used to hold the oil that is continuously circulated. (2) Lubricating oil pumps, which provide pressure for forcing "the oil through the oil passages and the bearings. Maximum system pressure is set by a relief valve. It must be adequate to provide the required oil flow through bearing clearances. The lube oil pumps are driven by chains or gears from the crankshaft, or by extension of the crankshaft or camshaft. They are located either inside or outside the crankcase.

When a centrifuge or oil-treatment system is installed to maintain clean lubricating oil, additional pumps are required to deliver oil to the treating equipment. (3) Lubricating oil circulating in the engine picks up friction heat from the bearings, heat from oil-cooled pistons, and also heat transferred from the combustion space to the oil film on the cylinder walls. This heat is removed by contact with water-cooled surfaces in the oil cooler of shell-and-tube construction.

No matter what system of filtering is employed, filters should provide the required flow rate at an acceptable pressure drop. Mechanical straining is usually accomplished by a fine-mesh screen.

Absorbent filters remove contaminants from the oil by sucking up or swallowing, as a sponge. Material used in them includes cotton waste, mineral wool, paper wood pulp, wool yarn, and felt.

Absorbent filters are those which hold, in a very thin layer, by adhesion, the molecules of dissolved substances, or liquids, to the surface of the solid filtering material.

Centrifugal filtering, or centrifuging, removes abrasive particles from the oil when the oil is rotated in an electrically-driven cylinder, at a very high velocity. The conventional centrifuge may be used to remove sludge, dirt, carbon particles and water from the lubricating oil.

II. Answer the questions.

1. What are the principal functions of the lubricating systems?

2. What is the crankcase oil used for?

3. How does a lubricator work?

4. Why is the valve-gear lube oil drained separately?

5. What are the parts of the pressure-lubricating system?

6. How may the lube oil pumps be driven?

7. What is the principle of centrifuging?

8. Where is the circulating lube oil cooled?

9. What types of filters are used for cleaning lubricating oil?

III. Translate into English.

1. Існують різні способи подачі мастила до рухомих частин дизеля.

2. Для запобігання прямого контакту тертьових поверхностей кожна робоча частина повинна змащуватися.

3. Масляні фільтри необхідні для очищення циркулюючого масла.

4. Після змащення всіх робочих поверхонь масло стікає в піддон, завершуючи цикл.

5. Якщо в'язкість масла занадто низька, воно не розділяє рухомі поверхні, а це призводить до металевого контакту і зайвого зносу.

6. Мастило має містити мінімальну кількість кислот, лугів і сторонніх часток.

FUEL SYSTEMS

If an engineer wants to do his job effectively he must have a good knowledge of the engine fuel system. The equipment used on board a diesel-driven ship for handling and controlling fuel oil belongs to several separate systems.

Fuel injection system performs the following functions: (1) it meters the quantity of the fuel required by the engine and maintains this quantity constant; (2) it injects fuel at the correct point in the cycle at all engine speeds and loads; (3) it begins and ends injection very quickly; (4) it injects fuel at the rate necessary to control combustion; (5) it atomizes fuel in the combustion chamber of each cylinder. The most important devices of this system are high- pressure fuel pumps and fiiel injection valves.

The engineer who has the main engine in his charge is responsible for the efficient operation, maintenance, adjustment and repair of the fuel injection system. Fuel fill and transfer system has the necessary tanks, piping, valves and pumps to receive fuel oil aboard, store it and pump it into the day tank. On either side of the main deck there is a ship's fuelling station equipped with one or more fill pipes. A fill pipe must be terminated with a connecting flange of international standard.

One end of the flexible hose passed over from a bunkering facility: fuel barge, fuel lighter, another vessel or shore fuelling facility, is connected to the ship's fill pipe. A container, called "drip tray" or "drip pan", must be placed under this flange-bolt connection to collect any leaks. The fill pipe runs from the fuelling station downward to the engine room where it is connected to a valve manifold. From that point, fuel oil transferred through the hose is directed to the various storage tanks.

When fuel oil is coming aboard, a specially designated rating, motorman or oiler, keeps a close watch on the levels in all tanks. He must keep the personnel stationed at the ship's fuelling station informed, by telephone or other means, of tank levels so that the delivery (rate) can be slowed down or stopped when necessary. A fuel tank must never be filled beyond the 95-percent level. Special overflow arrangements are provided for this purpose.

In most ships, storage tanks are located in the double bottom. The tanks, which are designed for heavy fuel oil (HFO), are provided with steam heating coils.

Every day the 3rd engineer transfers the amount of fuel consumed in a day from a storage tank to a settling tank by means of a fuel transfer pump. Water and sediment contained in the HFO settle out to the bottom of the settling tank.

The fuel treatment system starts where a fuel service pump takes suction from the settling tanks. HFO discharged by this pump flows through a strainer and fuel oil heater. Heated HFO is centrifuged (purified) in order to remove impurities and then it is pumped into a day tank.

A booster pump takes suction from the day tank and supplies it to the high-pressure fuel pumps through a filter.

Summing up the functions of the fuel systems of a diesel engine burning HFO one can say that they are designed for taking on, transferring, storing, settling, measuring, heating, straining, centrifuging, filtering, and supplying fuel oil into the engine's cylinders.

Before receiving fuel oil aboard, the person in charge of bunkering operations must take soundings or meter readings on all fuel tanks. It is his duty to know how much fuel is available on board, where it is, how much more can be taken on and the order in which the tanks should be filled. He maintains special records for this purpose and informs the chief engineer accordingly.

I. Answer the questions.

1. What are the five actions performed by the fuel injection system?

2. What jobs must the engineer responsible for the main engine do to maintain the fuel injection system in good working order?

3. What is the ship's fuelling station designed for and what is it equipped with?

4. The hose flange size is standardized, why?

5. What are the English names for the facilities, which deliver bunkers to the ships?

6 . Why is one of the tanks called the day fuel tank?

7. What professionals assist to bunkering operations and what are their duties?

8. What is an overflow arrangement needed for?

9. What are the functions of the transfer pump, booster pump, centrifuge and filter?

10. Did you understand the meaning of the terms "to take soundings", "to take meter readings", and "to maintain records"? Can you explain them at length?

11. Can you sum up the functions of the fuel systems?

II. Translate into English.

1. Сорт палива залежить від його головних складовихчастин.

2. Теплота згоряння визначається калориметром.

3. В'язкість характеризується швидкістю витікання палива.

4. На в'язкість палива впливає зміна температури.

5. Важке паливо зазвичай характеризується високою в'язкістю.

6. Паливо повинно спалюватися в розпиленому стані.

Lesson 17.

Engine Air Systems and Cooling Systems

ENGINE AIR SYSTEMS

Parts and accessories, which supply the cylinders of an engine with air for combustion, and remove the waste gases after combustion, are called intake and exhaust systems.

In the intake systems of all modern 2-stroke cycle engines and some 4-stroke cycle engines, a device, usually a blower is installed to increase the flow of air into the cylinders. This is accomplished by the blower compressing the air and forcing it into an air box or manifold (reservoir) which surrounds or is attached to the cylinders of an engine. Clearing the cylinder of the gases of combustion is called scavenging.

An increase in air flow into the cylinders of an engine can be used to increase power output, in addition to being used for scavenging. Since the power of an engine is developed by the burning of fuel, an increase of power requires more fuel; the increased fuel, in turn, requires more air, since each pound of fuel requires a certain amount of air for combustion. Supplying more air to the combustion spaces is called supercharging. In some 2-stroke cycle diesel engines, the cylinders are supercharged during the air intake simply by increasing the amount and pressure of scavenge air. The same blower is used for supercharging and scavenging. Supercharging a 4-stroke cycle diesel engine requires the addition of a blower to the intake system.

The system, which functions to convey gases away from the cylinders of an engine, is called the exhaust system. In addition to this principal function, an exhaust system may be designed to perform one or more of the following functions: muffle exhaust noise, quench sparks, remove solid material from exhaust gases, and furnish energy to a turbine-driven supercharger.

I. Answer the questions

1. What systems are spoken about in the text?

2. What is scavenging?

3. What is supercharging and how is it provided?

4. How is the supercharger driven?

5. What are the functions of the exhaust system?

ENGINE COOLING SYSTEMS

A great amount of heat is generated within an engine during operation. Combustion produces the greater portion of this heat; however, compression of gases within the cylinders and friction between moving parts add to the total amount of heat developed within an engine.

Of the total heat supplied to the cylinder of an engine by the burning fuel, only one-third is transformed into useful work; an equal amount is lost to the exhaust gases, and approximately 30 to 35 percent of the heat of combustion must be removed in order to prevent damage to engine parts. The greater portion of the heat, which may produce harmful results, is transferred from the engine through the medium of water; lubricating oil, air, and fuel are also utilized to aid in the cooling of the engine. All methods of heat transfer are utilized in keeping engine parts and fluids (air, water, fuel, and lubrication oil) at safe operating temperatures.

The cooling system may be of the open or closed type. In the open system, the engine is cooled directly by salt water. In the closed system fresh water, (or an antifreeze solution) is circulated through the engine. The fresh water is then cooled by salt water. In marine installations the closed system is the type commonly used.

The cooling system of an engine may include such parts as pumps, coolers, engine passages, water manifolds, valves, expansion tank, piping, strainers, connections, and instruments. Design and location of parts may differ considerably from one engine to another.

I. Answer the questions.

1. What are the sources of the heat generated in an engine?

2. How much heat is transformed into useful work?

3. How many percent of the heat must be removed from the engine by means of cooling?

4. What fluids are utilized for cooling purposes in an engine?

5. What parts does the water cooling system of an engine include?

II. Translate into English.

1. При роботі дизеля його частини сильно нагріваються.

2. Висока температура пошкоджує деталі дизеля, тому їх слідо холоджувати.

3. Для охолодження деталей дизеля використовують масло, дизельне паливо і дистильовану воду.

4. Для охолодження дизеля оптимально використовувати воду температурою 90-95 ° С.

5. Ефективністьо холодження деталей дизеля може знизитися через накип і корозію.

6. Структура системи охолодження залежить від розміру дизеля.

7. Найзручнішою охолоджуючою речовиною для морських дизелей є морська вода, бо не потрібні танки для зберігання і холодильники.

8. Але забортна вода рідко використовується в системі охолодження через ризик відкладення солі і корозії деталей двигуна.

9. Втулки циліндра можуть охолоджуватися морською або прісною водою, в той час як поршні зазвичай охолоджуються маслом.

10. Повітря не використовується для охолодження двигунів великої потужності, тому що ефективність такого охолодження низька.

11. Ефективність охолоджуючої системи морською водою зменшується, як тільки на внутрішніх частинах двигуна утворюється накип.

12. Необхідно примусове охолодження, для того, щоб підтримувати допустиму температуру головки (днища) поршня.

Lesson 18.

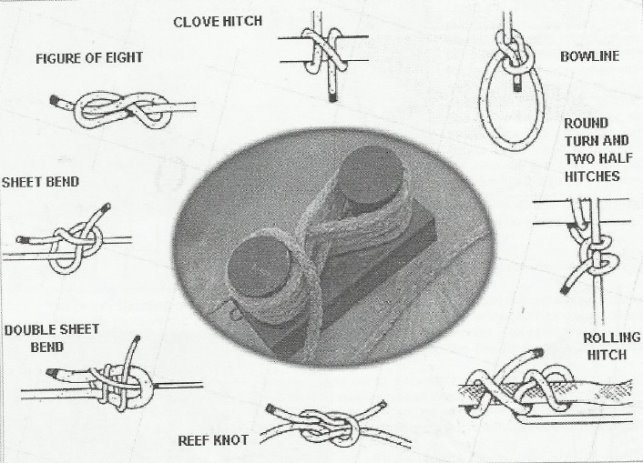

MOTORMAN TOOLS

A basic set of mechanics tools is required for working on engines – wrenches, a socket set, screwdrivers, hacksaw, crescent wrench, Vise Grips, etc.

1. Oil squirt can – preferably with flexible tip, for putting oil into the air inlet manifold.

2. Grease gun – preferably with flexible hose.

3. Feeler (thickness) gauges – from 0,001ʺ to 0,025ʺ (or the metric equivalent if clearances are specified in millimeters).

4. Oil filter clamp for spin-on-type filters. Such filters are extremely difficult to get on and off without this special purpose tool. More than one size may be required if the fuel filers are a different size.

5. Grinding paste. This is sold in three grades: coarse, medium and fine.

6. Suction cup and handle for lapping in valves.

7. Torque wrench is an indispensable tool for any serious mechanical work.

8. Ball peen hammer. Carpenters hammer with a jaw for pulling nails is mostly used but a ball peen hammer is far more useful. Hammers are specified by the weight.

9. Needle nose pliers – handy for all kinds of tasks – side-cutting needle nose pliers also have a wire-cutting jaw and are preferred.

10. Scrapers for cleaning up old gaskets.

11. Mallet or soft-faced hammer. A surprisingly valuable tool, especially if you need to knock an aluminium or cast-iron casting that might be cracked by a steel hammer.

12. Aligning punches – invaluable from time to time, especially the long ones. These punches are tapered.

13. Injector bar is about 15ʺ long, tapered to a point at one end, and with a heel on the other end. It is a very useful tool for prying or levering.

14. Allen wrenches – almost certainly required at some point. Keep am assortment on hand.

15. Hydrometer is needed for testing batteries.

16. Snap-ring pliers are very specialized equipment for the serious mechanic.

17. Valve-spring clamp.

18. Piston-ring expander.

19. Piston-ring clamp.

20. Gear puller. There are a number of gears and pulleys in any engine that just cannot be removed, unless you use some kind of a puller, without risking damage to engine castings or other parts. What should never be done is to put levers behind a gear to try and force it out – the effort generally ends in failure, and frequently in damage to some castings, the gear, the pulley, or the shaft.

21. Injector nozzle cleaning set includes a brass-bristle brush and the appropriate nozzle hole prickers.

A good toolkit represents a considerable expense but it will last a lifetime if cared for.

Lesson 19.

Personal Safety in the Engine Room.

Fire Prevention in the Engine Room

FIRE PREVENTION IN THE ENGINE ROOOM

Fire is a constant hazard at sea. It results in more total losses of ships than any other form of casualty. Almost all fires are the result of negligence or carelessness.

Two basically different types of equipment are available on board ship for the control of fires. These are small portable extinguishers and large fixed installations. The small portable extinguishers are for small fires which, by prompt on-the-spot action, can be rapidly extinguished. The fixed installation is used when the fire cannot be fought or restrained by portable equipment or there is perhaps a greater danger if associated areas were to be set on fire.

The use of fixed installations requires evacuation of the area containing the fire which, if it is the machinery space, means the loss of effective control of the ship. Various types of both portable and fixed firefighting equipment are available.

Fire protection on ships is provided by detection and fire-fighting equipment together with structural features which are intended to contain an outbreak of fire and the employment when required of non-combustible materials to prevent its spread.

Fire is the result of a combination of three factors: a substance that will burn, an ignition source, a supply of oxygen, usually from the air. These three factors are often considered as the sides of the fire triangle. Removing any one or more of these sides will break the triangle and result in the fire being put out. The complete absence of one of the three will ensure that a fire never starts.

Fires are classified according to the types of material which are acting as fuel. These classifications are also used for extinguishers and it is essential to use the correct classification of extinguisher for a fire, to avoid spreading the fire or creating additional hazards. The classifications use the letters A, B, C, D and E.

Class A : Fires burning wood, glass fibre, upholstery and furnishings.

Class B : Fires burning liquids such as lubricating oil and fuels.

Class C : Fires burning gas fuels such as liquefied petroleum gas.

Class D : Fires burning combustible metals such as magnesium and aluminium.

Class E : Fires burning any of the above materials together with high voltage electricity.

Many fire extinguishers will have multiple classifications such as A, B and C. Fire fighting at sea may be considered in three distinct stages, detection — locating the fire; alarm — informing the rest of the ship; and control — bringing to bear the means of extinguishing the fire.

There are four principal types of portable extinguisher usually found on board ship. These are the soda-acid, foam, dry powder and carbon dioxide extinguishers.

A variety of different fixed fire-fighting installations exist, some of which are specifically designed for certain types of ship. A selection of the more general installations will now be outlined.

1. Fire main system for cargo ships

2. Automatic water spray & water mist system for machinery protected area

3. Automatic foam induction system for machinery space fire

4. CO2 fire extinguishing installations for machinery spaces

5. Inert gas systems, inert gas generator

Machinery spaces are protected by fixed fire extinguishing installations, the fire main and extinguishers. Any statutory fixed installation must be operable from a position outside of the space. Any emergency stops for machinery and vent fans, means of securing openings and fuel tank valve shut-off devices, must also be located external to the space.

Engine room fires have been started by neglected oil leaks with the combustible material, in the form of fuel or lubricating oil dripping on to and being ignited by hot exhaust manifolds. There are a number of examples of combustible materials and potential ignition sources in machinery spaces.

A fire when it starts is usually small enough to be dealt with by a vigilant watchkeeper using a portable fire extinguisher. A fire which develops undetected in an unmanned machinery space (or one where the watchkeeper is in a control room) could require complete shutdown, evacuation and employment of the inert gas system. With unmanned spaces, an efficient alarm system for early detection is vital.

I. Answer the questions.

1. What is the most frequent reason for a fire?

2. What types of fire-fighting equipment are used on board ships?