Посібник з англійської мови для металургів

ДЕРЖАВНИЙ ПРОФЕСІЙНО-ТЕХНІЧНИЙ НАВЧАЛЬНИЙ ЗАКЛАД

НІКОПОЛЬСЬКІЙ ЦЕНТР ПРОФЕСІЙНОЇ ОСВІТИ

Посібник з англійської мови

для металургів

Програмно-педагогічні засоби:

ППЗ підтримки вивчення навчальних предметів

Лисенко М.М.

Нікополь

2020

Посібник з англійської мови для металургів. – Нікополь: НЦПО, 2020., 56с.

Посібник розрахований на широке коло користувачів: здобувачів освіти та викладачів профтехосвіти, а також усіх, хто вивчає англійську мову.

Посібник побудований на основі сучасної лексики англійської та української мов. Посібник сприятиме успішному оволодінню англійською мовою та формуванню професійних навичок металургів, розвитку інтелектуальних здібностей здобувачів освіти.

Упорядник:

Лисенко М.М.

Розглянуто та схвалено

на засіданні м/к суспільно-гуманітарних дисциплін

Протокол № 6 від 23.01.2020р.

Анотація

Посібник з англійської мови для металургів призначений для організації самостійної та додаткової роботи здобувачів освіти ПТНЗ, поглибленню та проведенню контролю знань з предмету «Англійська мова».

Система завдань посібника доповнює та розширює систему завдань навчальних підручників і посібників з предмету «Англійська мова». В посібнику подані опорні теоретичні положення теми, запитання самоконтролю знань, тестові завдання, завдання на розвиток логічного мислення.

Посібник побудований на основі сучасної лексики англійської та української мов. Також він сприятиме успішному оволодінню англійською мовою та формуванню професійних навичок металургів, розвитку інтелектуальних здібностей.

Посібник складається з 16 уроків, що дозволяють здійснювати поетапне, цілеспрямоване формування мовних навичок і умінь за допомогою системи завдань і вправ для професійно-спрямованого іншомовного читання.

До кожного уроку входять завдання і вправи на ознайомлення і тренування активного вокабуляра, а також вправи на говоріння та письмо.

Посібник з англійської мови для металургів містить велику кількість ілюстрованого матеріалу, таблиць, схем, що підвищує пізнавальну діяльність здобувачів освіти та якість знань, допомагає здобувачам освіти краще засвоїти і закріпити вивчений матеріал.

Посібник розрахований на широке коло користувачів: викладачів профтехосвіти та здобувачів освіти, що опановують професії: 8333 «Машиніст крана металургійного виробництва», 7215 «Стропальник», 8124 «Вальцювальник стана холодного прокату труб», 8124 «Пресувальник гарячих труб», 8124 «Клеймувальник гарячого металу (трубне виробництво)», а також усіх, хто вивчає англійську мову.

Зміст

Lesson 1……………………………………………………….…………………6

Lesson 2………………………………………………………..……..………...10

Lesson 3……………………………………………………………….………..13

Lesson 4…………………………………………………………….…………..17

Lesson 5……………………………………………………………….………..20

Lesson 6……………………………………………………………….………..23

Lesson 7………………………………………………………………….……..26

Lesson 8……………………………………………………….………………..30

Lesson 9………………………………………………………..……..…………34

Lesson 10……………………………………………………………….……….37

Lesson 11…………………………………………………………….………….41

Lesson 12……………………………………………………………….……….44

Lesson 13……………………………………………………………….……….47

Lesson 14………………………………………………………………….…….49

Lesson 15……………………………………………………….……………….52

Lesson 16………………………………………………………..……..………..55

Джерела………………….……………………………………………………..56

Lesson 1

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Surface [ˈsɜːfɪs]; supreme [suːˈpriːm]; nugget [ˈnʌɡ.ɪt]; malleable[ˈmæl.i.ə.bl̩]; scarcity [ˈskeə.sɪ.ti]; ornament [ˈɔː.nə.mənt]; ore [ɔːr]; require [rɪˈkwaɪə(r)]; deposit [dɪˈpɒzɪt]; obvious [ˈɒbviəs]; chemical [ˈkemɪkl] ; oust [aʊst]; surroundings [ səˈraʊndɪŋz ]; monetary [ˈmʌn.ɪ.tri ]; available [əˈveɪləbl ]; treatment [ˈtriːtmənt ]; lead [ liːd ].

Text

Metals in Perspective

Modern civilization is based on metals and millions of tons are extracted from the surface of the Earth every year. The place of metals in the modern world is supreme in importance. About three-quarters of all known chemical elements are metals.

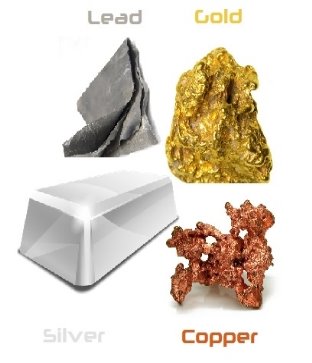

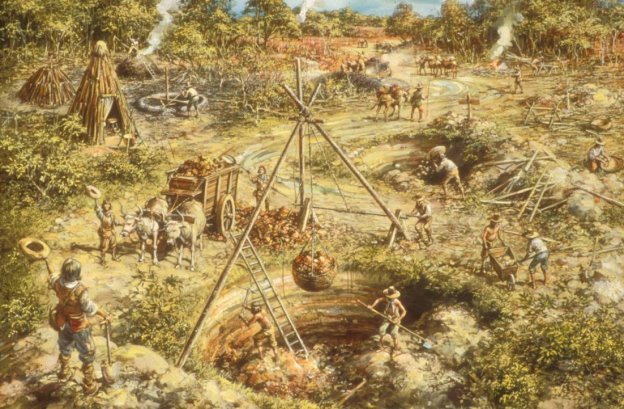

Since the Stone Age, man has found many materials he could work with. However, the materials that helped him most to develop were the metals. In many regions of the Ancient World man used lumps of native metals he could pick from the surface of the ground: gold nuggets, lumps of native copper and silver.

Archaeologists have found evidence of early metal-work dating as far back as 10,000 BC. Such finds were made in the Middle East, where deposits of copper were most plentiful. This does not mean that this metal was easy to find, but that there were more deposits in the Middle East than other parts of the world.

Archaeologists have found evidence of early metal-work dating as far back as 10,000 BC. Such finds were made in the Middle East, where deposits of copper were most plentiful. This does not mean that this metal was easy to find, but that there were more deposits in the Middle East than other parts of the world.

Copper seems to be the first metal which began to oust stone. The need for copper was great indeed. The advantages that copper had over stone as a material for weapons, tools, were obvious. The metal occurred naturally in the pure (free) state and had many good things about it: it could readily be worked to any shape, flattened, pointed and holed. At first, man made it into small things such as arrowheads. Before long, however, man noticed that when hammered copper becomes harder and stronger, but if it is held over a fire - soft, malleable, easy to work.

Gold is the most malleable of all the metals. It is much softer than copper and not very strong. But gold has been valued for thousands of years for its beautiful lustre and scarcity.

In about 4300 BC in the region of the Caspian Sea man discovered the process of smelting - how to extract the metals from their ores.

Two new metals came into use at this time - about 4,000 BC. The first was silver, prized in those days as it is today, for its beauty, and used for ornaments. It was sometimes found ‘free’, lying around, as was gold, but was mostly smelted from ores. The second metal was lead, a dull heavy metal, soft and easily shaped into cups and beakers. Lead is never found ‘free’; it has always been smelted from ore.

During the next 1,000 years the knowledge of the four metals far known - gold, copper, silver and lead - spread to other lands. Troy (home of Helen), near the Dardanelles, was the chief centre of trade and from there goods were carried by boat into Europe. The River Danube provided a highway deep into the continent, and the traders’ boats also took metal goods to all countries around the Mediterranean. Eventually they reached Britain, and the art of smelting and metal working became known in this country. Quite early in the history of metal the process of casting was used to shape metal.

So, during the many centuries of history man has learnt how to mine, smelt and work many metals. But iron - the chief metal of present times - has given the name of Iron Age to the most significant and productive period in the development of human society.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word- combinations given below. Use them in the sentences of your own.

Cучасна цивілізація, має величезне значення, шматки природного металу, родовище міді, зустрічається в чистому вигляді, піддається термічній обробці, ковкий, плавка (плавлення), обробляти метал, добувати руду, виплавляти метал, хімічний елемент, золотий самородок, перевага міді над каменем, твердий, м'який, блиск, виплавка чистого металу з руди витяг чистого металу з руди , свинець.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. the place of metals in the modern world

2. to pick from the surface of the ground

3. deposits of copper

4. the need for iron

5. to work to any shape

6. alongside with silver

7. a hard material

8. basic metallurgical arts

9. the most widely used metal

10. to work metals

1. надавати будь-яку форму

2. твердий матеріал

3. як і срібло

4.найбільш широко розповсюджений метал

5. обробляти метали

6. місце металів в сучасному світі

7. основні металургійні ремесла

8. потреба в залізі

9. підняти з поверхні землі

10. родовища міді

Exercise 3. Answer the following questions.

- What is modern civilization based on?

- What were the materials that helped man most to develop? Why?

- Was iron the first metal to oust stone?

- When did man start using metals?

- Where was evidence of early metal-work found?

- Why is gold widely used for ornaments?

- What was the 4th metal discovered and what are its properties?

Exercise 4. Complete the following statements by choosing the answer which you think fits best. Are the other answers unsuitable? Why?

1. Modern civilization is based on metals because:

a) three quarters of all known chemical elements are metals.

b) they can be used to produce a wide variety of things.

c) they are very cheap.

2. Gold has been used for ornaments for thousands of years because:

a) it has beautiful lustre.

b) it is not very strong.

c) it is scarce.

3. Heat treatment is used because:

a) it makes iron harder.

b) it protects iron against corrosion.

c) it improves the properties of iron.

4. Copper began to oust stone because:

a) it could be readily worked to any shape.

b) there was more copper than stone on the surface of the Earth.

c) it had a beautiful lustre.

Exercise 5. Give a written Ukrainian translation of the following definitions.

Copper - a ductile, malleable, reddish-brown metallic element that is an excellent conductor of heat and electricity. It is widely used either pure or in alloys such as brass or bronze.

Gold - a soft yellow, corrosion-resistant element, the most malleable ductile metal, occurring in veins and alluvial deposits and recovered by mining, or by panning sluicing. It is a good thermal and electrical conductor, generally alloyed to increase its strength, and used as an international monetary standard, in jewellery, for decoration and as a plated coating on a wide variety of electrical and mechanical components.

Gold - a soft yellow, corrosion-resistant element, the most malleable ductile metal, occurring in veins and alluvial deposits and recovered by mining, or by panning sluicing. It is a good thermal and electrical conductor, generally alloyed to increase its strength, and used as an international monetary standard, in jewellery, for decoration and as a plated coating on a wide variety of electrical and mechanical components.

Silver - a lustrous white, ductile malleable metallic element, occurring both uncombined and in ores such as argentite, having the lightest thermal and electrical conductivity of the metals. It is highly valued for jewellery, tableware and other ornamental use, and is widely used in coinage, photography, dental and soldering alloys, electrical contacts and printed circuits.

Lead - soft, malleable, ductile, bluish-white, dense metallic element, extracted chiefly from galena.

Lesson 2

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Сivilization [ˌsɪv.əl.aɪˈzeɪ.ʃən]; iron [ˈaɪən]; especially [ɪˈspeʃəli]; oxygen [ˈɒk.sɪ.dʒən]; guarded [ˈɡɑː.dɪd]; furnace [ˈfɜː.nɪs]; eventually [ɪˈventʃuəli]; toughness [ˈtʌfnəs]; superior [suːˈpɪəriə(r)]; Celtic [ˈkel.tɪk]; percentage [pəˈsen.tɪdʒ]; quenching [kwentʃ]; impurity [ɪmˈpjʊə.rɪ.ti].

Text

The Importance of Iron and Advent of Steel

Life seems impossible now without iron, the cheapest and most important metal we use. Iron is extracted from a rocky material called iron ore. Like many elements, iron is too reactive to exist on its own in the ground. Instead, it combines with other elements, especially oxygen, in ores. The chemical process for extracting a metal from its ore is called smelting.

The first people who discovered how to extract iron from iron ore were the Hittites, a powerful group of people living in Asia Minor and Syria - south of the Black Sea. They kept the process a closely guarded secret. The Egyptians, for example, had to pay the Hittites in gold four times the weight of iron and once deceived them with lumps of bronze covered with a thin layer of gold.

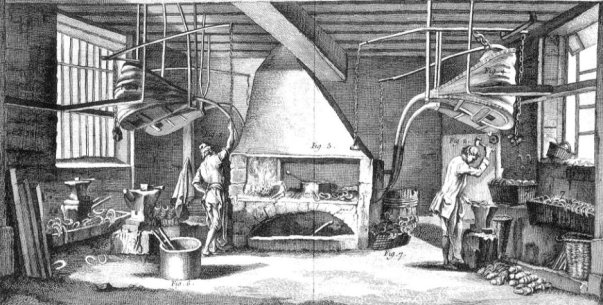

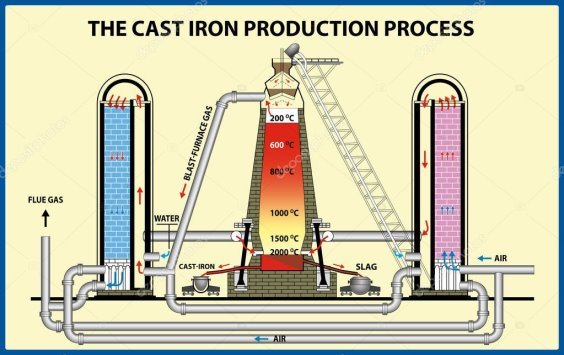

The smelting of iron was the most important metallurgical development. Iron-ore is plentiful all over the world, therefore it may seem surprising that such a long time elapsed before iron was produced. The reason was that the furnaces used to smelt copper were not hot

The smelting of iron was the most important metallurgical development. Iron-ore is plentiful all over the world, therefore it may seem surprising that such a long time elapsed before iron was produced. The reason was that the furnaces used to smelt copper were not hot

Sometimes the early iron-workers, or smiths, accidentally produced a steel article instead of an iron one. Steel is iron with a small percentage of carbon in it. The carbon came from the fuel in the furnace in which the iron was heated. The smiths later learned from experience how to introduce this carbon when they wanted to produce steel.

Steel is stronger than iron, and can be made stronger still by quenching, which is the sudden cooling, in water or other fluids, from red-heat. However, steel becomes very brittle when made extremely hard, and as each smith used his own method the quality of the steel varied a great deal. Often a sword made by a poor smith snapped just when it was most needed.

In those days furnaces were not hot enough to melt iron completely. To extract the iron from the iron-ore, the ore was heated as much as possible (reducing the iron to a ‘spongy’ consistency) and then hammered. This forced the bits of rock and other impurities out, leaving the iron behind. Great skill and dexterity were required, especially as tongs had not been invented and the hot metal was handled with green sticks.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word - combinations

given below. Use them in the sentences of your own.

Найдешевший метал; найважливіший метал; легко вступає в реакцію; Мала Азія; на південь / північ від; поширитися як на захід, так і на схід; покрити тонким шаром золота; твердість; виробництво знарядь праці і зброї; коваль; процентний вміст вуглецю; додавати вуглець; гартувати метал / сталь; крихкий; виробляти сталь; плавити залізо; рідка речовина; домішки; щипці.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. to extract iron

2. chemical process

3. a steel article

4. the fuel in the furnace

5. to learn from experience

6. the quality of the steel

7. to melt iron completely

8. to vary a great deal

9. to require great skill

10. steel becomes very brittle

11. red-heat

1. якість сталі

2. червоний жар

3. сталь стає дуже крихкою

4. паливо в топці

5. вчитися на досвіді

6. добувати залізо

7. повністю розплавити залізо

8. сильно варіювати

9. вимагати великої майстерності

10. нержавіюча сталь

11. хімічний процес

Exercise 3. Answer the following questions

1. Why is life impossible without iron? 2. Who first discovered how to extract iron from iron ore? 3. Why did they keep this process as a closely guarded secret? 4. How did the discovery of iron spread both east and west? 5. What is smelting? 6. What did the smiths do? 7. How did they get steel? 8. What process is called quenching? 9. Were the early smiths able to melt iron completely?

Exercise 4. Complete the following statements by choosing the answer which you think fits best. Are the other answers unsuitable? Why?

1. Man cannot live without iron because:

a) it is easy to mine it. b) it is very cheap.

c) he uses it in his everyday life.

2. The Hittite kept the process of smelting a top-secret because:

a) they wanted to use iron only for themselves.

b) it helped them to sell iron at high price.

c) they were very primitive people.

3. Early smiths could not produce proper steel because:

a) they did not know the right percentage of carbon.

b) the furnaces were not hot enough. c) they tried to introduce oxygen.

4. Great skill and dexterity were required to extract iron from ore because:

a) iron was heated very quickly.

b) the furnaces were not hot enough and tongs hadn’t been invented.

c) the hammer was too heavy.

Exercise 5. Give a written Ukrainian translation of the following sentences.

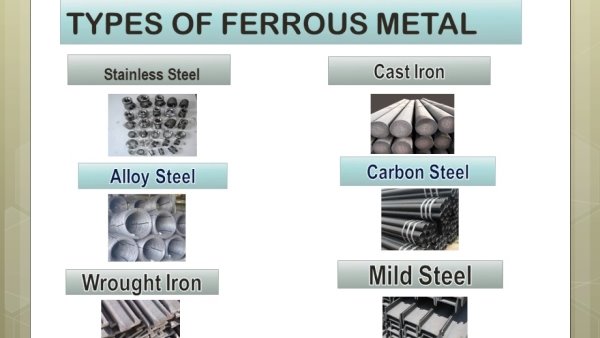

Iron is the commonest of all metallic elements (symbol Fe), used in various forms. Practically all of the iron is extracted from its chemical compounds in the blast furnace. A certain amount of harmful impurities is always present in iron ore. Ferrous metals are used in industry in two general forms: cast iron and steel.

Iron is the commonest of all metallic elements (symbol Fe), used in various forms. Practically all of the iron is extracted from its chemical compounds in the blast furnace. A certain amount of harmful impurities is always present in iron ore. Ferrous metals are used in industry in two general forms: cast iron and steel.

Steel is iron containing to 1.7 per cent carbon content. Pure iron is not used in industry because it is too soft.

Cast iron is a hard, brittle , non-malleable iron-carbon alloy containing 2.0 to 4.5 % carbon, 0.5 to 3% silicon and lesser amounts of sulphur, manganese and phosphorus.

Lesson 3

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Reign [ reɪn ]; conqueror [ˈkɒŋ.kər.ər ]; manufacture [ˌmænjuˈfæktʃə(r)]; hearth [hɑːθ ]; value [ˈvæljuː]; utensils [juːˈten.sɪl]; valuables [ ˈvæl.jʊ.bl̩z ]; wrought [ rɔːt ]; import [ ˈɪmpɔːt ]; prohibit [prəˈhɪb.ɪt]; knives [naɪvs]; key [ kiː ]; spur [ spɜːr ]; diameter [ daɪˈæm.ɪ.tər ].

Text

Iron in the Middle Ages

Iron came to Britain long before the reign of William the Conqueror. There is evidence that the forging of iron was the chief trade of the city of Glousester. Yet iron continued to be scarce in England.

For some hundred years after the Norman Conquest considerable quantities of iron and steel were exported to Britain by Germany and other continental countries. The merchants who brought metals were known as “German merchants of the Steelyard”. The great quantities of iron and steel were sold at the Steel Yard in London.

For some hundred years after the Norman Conquest considerable quantities of iron and steel were exported to Britain by Germany and other continental countries. The merchants who brought metals were known as “German merchants of the Steelyard”. The great quantities of iron and steel were sold at the Steel Yard in London.

According to the Act of Parliament no iron was to be carried out of the country. Some iron was manufactured in England in the reign of Henry III, but much was still imported from Germany and later from Spain.

During the reign of Edward I (1239 - 1307) there were seventy-two hearths in the Forest of Dean - a source of iron ore. By the time of Edward III (1312 - 1377) the chief centres were Kent and Sussex. That iron was still of great value is shown by an inventory of the king’s possessions, in which his iron pots, pans, and other household utensils are classed as jewels and valuables.

No sensational developments in the manufacture of iron and steel had taken place; the local smiths converted the raw ore into wrought iron by means of charcoal obtained by burning timber from the forest round about and worked up this iron into the required shapes.

In the 14th century the direct extraction of wrought iron from the ore was gradually displaced by first carbonizing the metal, so turning it into cast iron. This displacement method has continued steadily up to the present day.

During the 14th and 15th centuries England continued to import iron and steel from the continent. The growing importance of the industry gave its owners a political influence that grew steadily from that day to this. Improvements in the manufacture of iron had taken place during this period, and the ironmasters succeded in getting Parliament to make laws prohibiting the importation into England of any iron or steel goods already made there. In 1483, for example, an Act was passed prohibiting the importation of knives, tailors’ shears, scissors and irons, grid-irons, stock-locks, keys, hingers, spurs, bits, stittups, buckles for shoes, iron wire, iron candlesticks, grates and many other such objects.

Minor advances in the art of making iron continued up to the times of Elizabeth I and James I. Production increased, especially in Sussex. By this time the blast furnace had established itself for the smelting of iron. It continued slowly to rise higher and increase in diameter. The immediate problem confronting the iron manufacturer of the 16th century was the growing shortage of wood from which to make charcoal.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word – combinations given below. Use them in the sentences of your own.

Велика кількість заліза і сталі; імпортувати з; джерело залізної руди; високо цінуватися; перетворювати; оброблене залізо; деревне вугілля; постійно зростати; забороняти; опис; цінні речі; обпалювати (коксувати); решітка (сітка); дужка; діаметр; безпосередні проблеми, що стоять перед.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. long before

2. to continue steadily up to the

present day

3. in the reign of

4. to displace gradually by

5. the growing importance

6. to succeed in

7. the great quantaties of

8. blast furnace

1. велика кількість

2. під час правління

3. зростаюча важливість

4. досягти успіху в

5. доменна піч

6. задовго до

7. тривати без змін до теперішнього часу

8. поступово замінити

Exercise 3. Answer the following questions

1. When did iron first come to Britain? 2. Was it imported from Germany? 3. What shows that iron was of great value in Medieval Britain? 4. What displaced the direct extraction of wrought iron? 5. Why did the owners of metal industry get a political influence? 6. Did Parliament play an important role in the development of metal industry?

Exercise 4. Complete the following statements by choosing the answer which you think fits best. Why are the other answers unsuitable?

1. That iron was of great importance is shown by an inventory of king’s

possessions because:

a) things made of iron were classed as jewels and valuables.

b) King Edward III wrote about their value himself.

c) things made of iron could be used only by the king.

2. The owners of metal industry got a political influence because:

a) they had much money.

b) the industry grew in importance.

c) people wanted so.

3. The importation into England of any iron or steel goods was prohibited

by Parliament because:

a) it was necessary to develop native industry.

b) the native production stopped.

c) England didn’t need them.

4. The immediate problem confronting the iron manufacturer was:

a) the lack of skills in steel-making.

b) the growing shortage of wood.

c) the establishment of the blast furnaces.

Exercise 5. Give a written Ukrainian translation of the following passages.

1. The chemical process for extracting a metal from its ore is called smelting. Iron ore is heated with limestone and coke, which is mostly made up of carbon. Coke and limestone remove the unwanted parts of the iron ore to leave almost pure iron, which still contains some carbon. Steel is made by removing more carbon and adding other metals.

2. Gold is much softer than copper, so it is easier to hammer into shape. It is not very strong. A gold knife might look very fine but would not have been much use for skinning a bear, so from early times gold became the metal for ornaments. Copper is much harder; it would have been much more difficult for early man to shape; but the finished article was more durable.

3. These metal-workers were masters of the ancient craft of gold-beating, a process by which gold is beaten between skins until it is reduced to a very thin sheet. The Egyptians could produce sheets only one five-thousandth of an inch thick, and used them for gilding wooden statues and for other decorative purposes.

Lesson 4

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Liquid [ˈlɪkwɪd]; spongy [ˈspʌn.dʒi]; design [dɪˈzaɪn]; liquefy [ˈlɪk.wɪ.faɪ]; automatically [ˌɔː.təˈmæt.ɪ.kəl.i]; metallurgy [məˈtæl.ə.dʒi]; technical [ˈteknɪkl]; throughout [θruːˈaʊt].

Text

Iron - Smelting without Charcoal

The First Blast Furnaces

So far, no furnace in Europe had been hot enough to melt iron to a liquid state. All that could be produced was a ‘spongy’ mass from which impurities had to be hammered out. However, design of furnaces improved over the centuries, and about the year 1400 very efficient blast furnaces were introduced by the Germans. They had found that a blast of air from water-powered bellows increased the temperature, though the iron still did not liquefy. It became soft and spongy, worked its way down through the burning charcoal, and collected at the bottom of the furnace.

Furnaces were usually built about ten or fifteen feet high, but to economise on fuel a new one was built thirty feet high. Although the internal temperature in this was no higher, the iron arrived at the bottom in a completely liquid state. Not only could the metal be run off into moulds, but many of the impurities (which had previously to be hammered out) separated automatically from the melted iron. The reason for this tremendous stride in metallurgy was simple: the height of the furnace. The soft ‘sponge’ iron took so long to seep down through the charcoal that it absorbed a great deal of carbon. It became carburised, and as the melting point of carburised iron is 350o C less than ‘sponge’ iron, it became liquid.

Furnaces were usually built about ten or fifteen feet high, but to economise on fuel a new one was built thirty feet high. Although the internal temperature in this was no higher, the iron arrived at the bottom in a completely liquid state. Not only could the metal be run off into moulds, but many of the impurities (which had previously to be hammered out) separated automatically from the melted iron. The reason for this tremendous stride in metallurgy was simple: the height of the furnace. The soft ‘sponge’ iron took so long to seep down through the charcoal that it absorbed a great deal of carbon. It became carburised, and as the melting point of carburised iron is 350o C less than ‘sponge’ iron, it became liquid.

By about the year 1600, iron production in Britain was beginning to suffer from lack of fuel. For 3,000 years all iron-smelting, both here and abroad, had been done with charcoal. Charcoal is partly-burned wood. In Britain, timber was running short and it was impossible for the iron-makers to equal the output of a country such as Sweden, where timber was abundant.

Fortunately for Britain a Quaker, Abraham Darby, found a way to do without charcoal altogether. In his iron factory at Coalbrookdale, Shropshire, he made many experiments using coke, and finally succeeded. There were technical difficulties to overcome, and at first Darby kept the process secret for the benefit of his family. Later his methods were adopted throughout Europe. No longer dependant on dwindling forests, Britain remained her position as a leading iron producer.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word-combinations given below.

Домішки; доменна піч; потік повітря; рідкий стан; висотою в десять футів; економити на паливі; температура всередині печі; великий прогрес в металургії; поглинати вуглець, недолік палива; кокс; досягти успіху; проводити досліди; долати труднощі; по всій Європі; відновити свої позиції.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. to melt iron to a liquid state

2. to hammer out impurities

3. efficient blast furnaces

4. at the bottom of the furnace

5. to separate from

6. melting point

7. to equal the output

8. to be abundant

9. for the benefit of

1.видалити домішки

2. відокремлювати від

3. точка плавлення

4. зрівняти результати

5 розплавити залізо до рідкого стану

6. бути в достатку

7. на благо, заради

8. на дні печі

9. високопродуктивні доменні печі

Exercise 3. Answer the following questions:

1. When did the first blast furnaces appear? 2. What is the work of a blast furnace based on? 3. Does the productivity of blast furnaces depend on their height? 4. Why did iron production in Britain begin to suffer? 5. What did Abraham Darby introduce into the process of iron-making?

Exercise 4. Complete the following statements by choosing the answer which you think fits best. Are the other answers unsuitable?Why?

1. No furnace in Europe could melt iron to a liquid state because:

a) there were too many impurities in it.

b) they were not hot enough.

c) water-powered bellows didn’t work properly.

2. The reason for the tremendous stride in metallurgy was:

a) the height of the furnace.

b) the shape of the furnace.

c) the internal temperature of the furnace.

3. Iron production in Britain began to suffer from:

a) the exhaustion of the deposits of iron ore.

b) political situation.

c)lack of fuel.

4. Abraham Darby succeeded in his experiments to do without charcoal

because:

a) he used coke.

b) he hammered out the impurities.

c) he mixed iron with carbon.

Exercise 5. Give a written Ukrainian translation of the following passage.

1. In addition the rapid developments in the use of iron and steel during the Industrial Age brought with them greatly increased demand for other metals, particularly copper, tin and lead. Moreover, the demand was not only for greater tonnages but also for a far greater variety of metals. Many of these metals were one hundred years ago little known names in the periodic table, but have now come into prominence and have become marketable commodities. It is accordingly not surprising that there have been more notable advances in metallurgy during the century under review than in the whole history of this ancient art.

2. Limestone is included in the furnace because it mixes and combines with sand, clay and stones in the ore. They form a waste material, called slag, which floats on top of the molten metal.

Lesson 5

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Engine [ˈendʒɪn]; industrial [ɪnˈdʌstriəl]; industry [ˈɪndəstri]; revolution [ˌrevəˈluːʃn]; multiplied [ˈmʌl.tɪ.plaɪ]; designed [dɪˈzaɪn]; forge [fɔːdʒ]; shaft [ʃɑːft]; required [rɪˈkwaɪər]; accurately [ˈæk.jʊ.rət]; anvil [ˈæn.vɪl]; machine [məˈʃiːn]; extrusion [ɪkˈstruːd]; tremendous [trɪˈmen.dəs]; engineering [ˌendʒɪˈnɪərɪŋ]; reverberate [rɪˈvɜː.bər.eɪt].

Text

The Vast Growth of the Iron and Steel Industry

When James Watt invented the steam engine in the latter part of the 18th century, the whole industrial scene changed. Steam power made possible the ‘Industrial Revolution’ in Britain. Vast quantities of metal were needed for the railways pioneered by the Stevensons, and the huge iron ships and bridges of Brunel. In Sheffield, the centre of the iron and steel industry, the output of metals multiplied fifty times in thirty-five years.

During this expansion, improved tools were invented for use in the factories and many steam-powered tools were invented and developed. One of the most famous of these tools was the steam-hammer designed by James Nasmyth about 1830. It was used to forge the huge shafts and plates required in the ships of the time, and could be accurately controlled to give heavy blows or light taps. In fact, to impress visitors to the foundry an egg was placed on the anvil and cracked by the hammer without breaking the egg shell. Other machine-tools invented and developed included the rolling-mill which could roll metal, either hot or cold, into thin sheets.

A British metallurgist Henry Cort took out a patent in 1783 for a mill to roll iron sheets and bars. In 1784 he improved the puddling process by hollowing out the bottom of the reverberatory furnace so as to contain the molten metal in this puddle. Railway lines could be made in this way, the hole in the press being suitably shaped to the section of the railway-line. Puddling played a great role in the development of iron and steel industry in Britain during the Industrial Revolution.

These tremendous advances in engineering were matched by improvements in the quality of metals, and the metallurgists were as active and successful as the engineers. Between 1750 and 1850 no less than thirty-five more metals were discovered. Many of these were unimportant but three were outstanding, nickel, cobalt, and manganese, the latter to play a vital part in steel production.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word-combinations. Use them in the sentences of your own.

Винайти паровий двигун; Промислова революція; збільшитися в п'ятдесят разів; модернізовані засоби праці; винаходити; паровий молот; вісь (шпиндель); ливарний цех; прокатний стан; видавлювати поглиблення (порожнину); відбивна піч.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. the latter part of the century

2. vast quantities of smth

3. output of metals

4. to impress visitors

5. anvil

6. railway lines

7. advances in engineering

8. the quality of metals

9. to play a vital part

10. steel production

1. виробництво сталі

2. ковадло

3. прогрес в техніці

4. якість металів

5. відігравати важливу роль в

6. остання частина / кінець століття

7. виробництво металів

8. залізничні рейки

9. величезну кількість

10. справляти велике враження на відвідувачів

Exercise 3. Answer the following questions

1. When did James Watt invent the steam engine? 2. What was the result of his invention? 3. Where was steam-hammer first used? 4. Who invented the rolling-mill? 5. What is the purpose of the rolling mill? 6. What is the puddling process used for? 7. Were any new metals discovered between 1750 and 1850?

Exercise 4. Choose the word or phrase which best completes each sentence.

1. . . . iron is a relatively soft silvery metal.

a) clean b) mixed c) pure

2. All but 20 of the over 100 elements identified to date are . . .

a) metals b) gases c) non-metals

3. Only 7 metals are common in the earth’s . . .

a) surface b) crust c) underground

4. Copper was the first metal . . . by man.

a)invented b) opened c) discovered

5. The steam-hammer was . . . by James Nasmyth.

a) elaborated b) designed c) worked out

6. Gold, silver and copper have always been . . . for their qualities.

a) praised b) respected c) valued

Exercise 5. Give a written translation of the following passages.

Exercise 5. Give a written translation of the following passages.

1. Thomas, Sidney Gitchrist (1850 - 1885), a British metallurgist. Educated at Dulwich college. Served as a clerk at the Court of London and attended evening lectures at the Royal Mining School. While looking for ways and means of making steel from high-phosphorus pig iron in the Bessemer converter, he devised (with assistance from his cousin Peter Gilchrist) in 1878 what later became known as the Thomas-Gilchrist process in England or the Thomas process on the continent. Took out several patents covering the process between 1877 and 1882. Predicted that the high-phosphorus slag from his process could be used as a soil conditioner and stimulant to plant growth.

Lesson 6

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Forward [ˈfɔːwəd]; engineer [ˌendʒɪˈnɪə(r)]; royal [ˈrɔɪəl]; society [səˈsaɪəti]; patent [ˈpeɪ.tənt]; technology [tekˈnɒlədʒi]; experimental [ɪkˌsper.ɪˈmen.təl] spurt [spɜːt]; subside [səbˈsaɪd]; manganese [ˈmæŋ.ɡə.niːz ]; chromium [ˈkrəʊ.mi.əm].

Text

More Progress in Steel Production

Iron coming from a blast furnace is called pig-iron, and still contains many impurities which have to be removed before it can be converted into steel. During the Industrial Revolution the demand for steel was so great that better and quicker methods of producing it became necessary. A big step forward was made with the invention of the ‘Bessemer Converter’.

Henry Bessemer (1813 - 1898) was a British civil engineer and inventor. He was elected to the London Royal Society in 1879. During his life-time he patented over a hundred inventions in various fields of technology.

Henry Bessemer (1813 - 1898) was a British civil engineer and inventor. He was elected to the London Royal Society in 1879. During his life-time he patented over a hundred inventions in various fields of technology.

Henry Bessemer’s idea was that the impurities would be burned away if air was blown through molten pig-iron.

An experimental vessel to contain 7 cwts of molten pig-iron was set up in Bessemer’s factory. Air pipes led into the bottom of the vessel, and when the air was turned on, huge flames and showers of sparks shot out of the mouth of the converter, followed by spurts of molten metal and slag. Bessemer and his workers could only retreat and hope for the best. They could not turn off the air because the air-valve had been placed too near to the converter. However, after ten minutes the eruption subsided and it was found that the iron was free of impurities.

The new process was widely adopted, and converters were built which could purify several tons of pig-iron in half-an-hour - an enormous improvement on previous methods. The Bessemer ‘blow’, with flames shooting high into the air, is one of the most dramatic sights in steel manufacture.

Other methods followed, the Siemens ‘open hearth’ furnaces were slower than the Bessemer converter but gave better control. “Electric arc’ furnaces were introduced later.

Two metals, manganese and chromium, discovered in 1774, were to play an important role in steel manufacture. Small quantities of manganese in steel adds greatly to its strength. Chromium is used in the manufacture of stainless steel.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word- combinations. Use them in the sentences of your own.

Чавун (штиковой чавун); містити домішки; видаляти домішки; перетворювати в сталь; потреба в сталі; інженер-будівельник; випалити; запатентувати; шлак; вантуз; модернізація існуючих методів; марганець; хром; збільшувати міцність; відігравати важливу роль у виробництві сталі.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. to produce steel

2. to make a big step forward

3. air pipes

4. in various fields of technology

5. to hope for the best

6. to adopt widely

7. to turn off

8. the most dramatic sight

9. electric arc furnace

10. open hearth furnace

1. найбільш величне видовище

2. електродугова піч

3. виробляти сталь

4. сподіватися на краще

5. вимикати

6. вентиляційні труби

7. мартенівська піч

8. зробити великий крок вперед

9. розповсюджено

10. в різних областях техніки

Exercise 3. Answer the following questions.

1. What differs pig-iron from steel? 2. Who made the revolution in steel industry? 3. What was the main idea of Bessemer’s experiment? 4. What are the advantages and disadvantages of open hearth furnaces over Bessemer’s converter? 5. How can we increase the strength of steel? 6. What is chromium used for?

Exercise 4. In the text there are some verbs which in combination with prepositions acquire another meaning, complete the sentences given below using them.

to set smth off; to set in; to set out; to turn someone down;

to turn smth in; to turn someone on; to turn out

1. Let’s . . . early tomorrow. It’ll take us long to get to Stratford. 2. We’ve had . . . his proposal. It’ll be too expensive to make use of it. 3. His lectures . . . to be very interesting. 4. It’s been very cold the last few days. I think the winter . . . already. 5. Rock music really . . . me. 6. Bill is a hard-working student. He . . . two essays every week. 7. He . . . to work on the project several days ago.

Exercise 5. Choose the word or phrase that best completes each sentence. Explain your choice.

1. The . . . of steel at Robertsbridge began in 1565.

a) production b) output c) manufacture

2. The importance of Bessemer’s discovery was that . . . pig iron was transformed into steel within some thirty minutes.

a) molten b) liquid c) hard

3. In the end of the 18th century . . . of metals improved greatly with the help of new methods.

a) quantity b) quality c) number

4. One of the properties of metals is their specific . . .

a) shining b) luster c) glitter

5. All metals except mercury are . . . substances.

a) hard b) tough c) heavy

6. Converters can . . . several tons of pig iron in a short period of time.

a) clean b) clear c) purify

7. Impurities must be removed before pig iron can be . . . into steel.

a) converted b) transformed c) made

8. Chromium was . . . in 1774.

a) opened b) found c) discovered

Exercise 6. Give a written translation of the following passage.

The technique of making steel had not fallen into oblivion. In Anglo-Saxon literature many references are made to steel and also to ‘steeling’. Conversion of soft wrought iron into steel by cementation continued to be practiced. The technique seems to have been improved by the Danes locally to satisfy the demands of small economic units.

The technique of making steel had not fallen into oblivion. In Anglo-Saxon literature many references are made to steel and also to ‘steeling’. Conversion of soft wrought iron into steel by cementation continued to be practiced. The technique seems to have been improved by the Danes locally to satisfy the demands of small economic units.

The conquering Normans were greatly impressed by the industrial efficiency they found in England. German skilled workers were accustomed to reside in England because of the high level the Anglo-Saxon had attained in metal - making. For example, knives made in England, were valued much in France during the Middle Ages.

Lesson 7

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Source [sɔːs]; mightiest [ˈmaɪtɪɪst]; area [ˈeəriə]; synonymous [sɪˈnɒn.ɪ.məs]; crucible [ˈkruː.sɪ.bl̩]; unequalled [ʌnˈiː.kwəld]; uniformity [ˈjuː.nɪ.fɔːm]; revolutionised [ˌrev.əˈluː.ʃən.aɪz]; percentage [pəˈsen.tɪdʒ]; phosphorus [ˈfɒs.fər.əs]; legacy [ˈleɡ.ə.si]; frequency [ˈfriː.kwən.si].

Text

Steel Production in Sheffield

Today, Sheffield is one of the main sources of the world’s best steel, the mainspring for the mightiest industries of mankind.

Yet, as a steelmaking centre, Sheffield built its reputation only about a century and a half ago. The location of the industry in the lower valley of the Don owed something at that time to the older established edge tool crafts, based originally on imported steel into an area with fuel and water power available, but the main advantage of South Yorkshire was the abundant supply of coal and access to Baltic transport.

Yet, as a steelmaking centre, Sheffield built its reputation only about a century and a half ago. The location of the industry in the lower valley of the Don owed something at that time to the older established edge tool crafts, based originally on imported steel into an area with fuel and water power available, but the main advantage of South Yorkshire was the abundant supply of coal and access to Baltic transport.

The name of the city has become synonymous with quality, craftsmanship and traditional skills. Skills that have become secrets handed down from father to son, that have created the city’s proud boast that the words ‘Sheffield, England’ on any product are a certain guarantee of quality.

The modern steel industry on which the city’s fame partly rests, only really began with the invention of the crucible process by Benjamin Huntsman, who settled in Handsworth about 1740. His steel was of unequalled uniformity of quality and its use revolutionised the making of tools.

By 1835 Sheffield was already established as the centre of tool-steel manufacture in Britain. Bessemer’s invention of his converter steelmaking, first practised in Sheffield and bringing the era of bulk steels, put Sheffield further ahead. Sheffield chose, however, to develop on the lines of the manufacture of alloy and special steels for special purposes and with distinct characteristics. There are numerous types of steel made but they can mainly be divided into a few wide groups: low and medium carbon steels: high carbon and high quality alloy tool steels; special alloy constructional and die steels; stainless and heat-resisting steels, low steels from which permanent magnets for the electrical industries are made (including alloys which are not true steels but made principally in Sheffield by the same process).

By 1835 Sheffield was already established as the centre of tool-steel manufacture in Britain. Bessemer’s invention of his converter steelmaking, first practised in Sheffield and bringing the era of bulk steels, put Sheffield further ahead. Sheffield chose, however, to develop on the lines of the manufacture of alloy and special steels for special purposes and with distinct characteristics. There are numerous types of steel made but they can mainly be divided into a few wide groups: low and medium carbon steels: high carbon and high quality alloy tool steels; special alloy constructional and die steels; stainless and heat-resisting steels, low steels from which permanent magnets for the electrical industries are made (including alloys which are not true steels but made principally in Sheffield by the same process).

Sheffield, the initiator, is in fact the place where the chief discoveries respecting steel and its wonderful powers and possibilities have been made by means of trial and error. Here in 1859 Robert Forester Mushet, made possible the production of a mild all-purpose steel in large quantities. A further process was also introduced, the Siemens-Martin process. In his open-hearth process heat was saved and intensified by using for the blast hot air from the furnace instead of cold. This enabled manufacturers to use ore with a smaller percentage of carbon and a higher percentage of impurities such as phosphorus, as the blast cleared away the harmful elements more thoroughly. Both of these improvements enormously cheapened the production of the average steels in ordinary use.

Sheffield, the initiator, is in fact the place where the chief discoveries respecting steel and its wonderful powers and possibilities have been made by means of trial and error. Here in 1859 Robert Forester Mushet, made possible the production of a mild all-purpose steel in large quantities. A further process was also introduced, the Siemens-Martin process. In his open-hearth process heat was saved and intensified by using for the blast hot air from the furnace instead of cold. This enabled manufacturers to use ore with a smaller percentage of carbon and a higher percentage of impurities such as phosphorus, as the blast cleared away the harmful elements more thoroughly. Both of these improvements enormously cheapened the production of the average steels in ordinary use.

The industrial legacies provided by these early steelfounders created a sound basis for development. The Siemens open hearth furnace, the converter process invented by Alexandre Tropenas, the electric arc furnace, the high-frequency induction furnace have taken their places in due course. Low-frequency induction melting has since been introduced into the city and high-frequency induction heating is helping heat-treatment and other processes in the manufacture of Sheffield’s steels and steel products.

Lexical Exercises

Exercise 1. Find the English equivalents for the following words and word-combinations given below. Use them in the sentences of your own.

Джерело; головна рушійна сила; місце розташування; гострий ріжучий інструмент; перевага; доступ до; майстерність; легована сталь; відмінна характеристика; сталь з низьким вмістом вуглецю; будівельна сталь; нержавіюча сталь; жаростійка сталь; сплав; здешевити виробництво; засновники сталеливарної промисловості; високочастотний нагрів; низькоякісна плавка; термічна обробка.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. a steelmaking centre

2. abundant supply

3. water power

4. crucible steel

5. uniformity of quality

6. a certain guarantee of quality

7. bulk steel

8. die steel

9. permanent magnet

10. by means of trial and error

11. mild steel

1. тигельна сталь

2. необроблена сталь

3. однаково високу якість

4. штампова сталь

5. певна гарантія якості

6. постійний магніт

7. необмежений запас

8. шляхом проб і помилок

9. м'яка (маловуглецева) сталь

10. водяна енергія

11. центр сталеливарного

виробництва

Exercise 3. Answer the following questions.

1. Why did Sheffield become a steelmaking centre? 2. When did the modern steel industry begin? 3. What types of steel were produced in Sheffield? 4. Which processes of steel-making were first introduced in Sheffield? 5. How can the Siemens-Martin process be described?

Exercise 4. Choose the word or phrase that best completes each sentence.

1. Such men as Bessemer, Siemens and Mushet were . . . the steel material.

a) improving b) discovering c) introducing

2. Only comparatively small . . . of the steel could be melted at one time in the first crucibles.

a) numbers b) quantities c) amounts

3. Bessemer’s converter was the first major . . . after Huntsman’s crucible.

a) discovery b) invention c) innovation

4. South Yorkshire used to give the . . . supply of coal.

a) great b) rich c) abundant

5. Bessemer’s process helped to burn . . . all the carbon.

a) out b) in c) up

6. South Wales - . . . near the sea was convenient for the importation of Spanish ore.

a) located b) present c) accommodated

7. Almost all important discoveries were made by means of trial and . . .

a) mistakes b) fault c) error

Exercise 5. Give a written translation of the following passage.

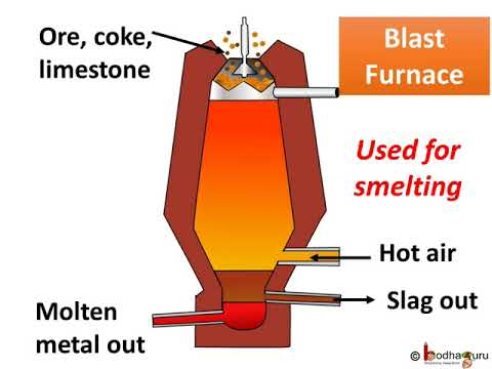

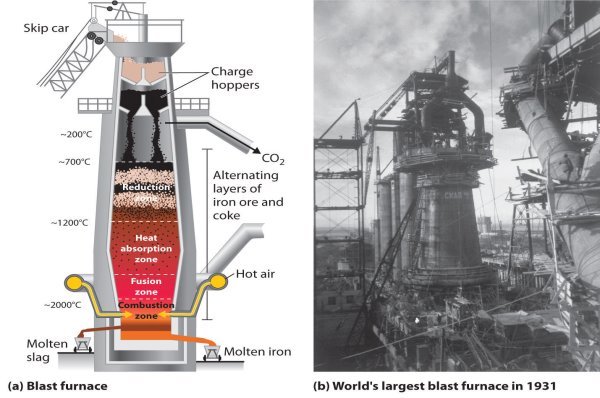

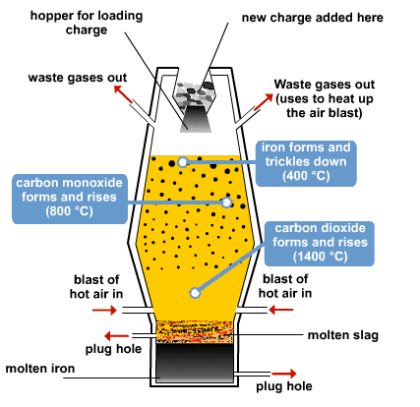

THE BLAST FURNACE

Iron is extracted from iron ore in blast furnaces. The biggest are 60m (200ft) high, produce 10,000 tonnes of iron a day, and work non-stop for 10 years. The furnace gets its name from the blast of hot air that heats up the raw materials. These are iron ore, limestone, and coke (a form of carbon). As carbon is more reactive that iron, it grabs the oxygen from the iron ore, leaving iron metal behind.

Iron is extracted from iron ore in blast furnaces. The biggest are 60m (200ft) high, produce 10,000 tonnes of iron a day, and work non-stop for 10 years. The furnace gets its name from the blast of hot air that heats up the raw materials. These are iron ore, limestone, and coke (a form of carbon). As carbon is more reactive that iron, it grabs the oxygen from the iron ore, leaving iron metal behind.

Limestone is included in the furnace because it mizes and combines with sand, clay, and stones in the ore. They form a waste material, called slag, which floats on top of the molten metal.

The chemical reactions begin when hot air is blasted into the furnace. As the coke burns, the carbon in it gets enough energy to react with oxygen from the air to form first carbon dioxide and then carbon monoxide. The carbon monoxide takes oxygen atoms from the iron oxide to leave carbon dioxide and iron metal. Temperature inside the furnace reaches 1,900oC, melting the iron which sinks to the bottom.

Lesson 8

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Originated [əˈrɪdʒ.ɪ.neɪt]; per cent [pə(r) sent]; crude [kruːd]; brought [brɔːt]; major [ˈmeɪdʒə(r)]; recession [rɪˈseʃ.ən]; product [ˈprɒdʌkt]; produce [prəˈdjuːs]; production [prəˈdʌkʃn]; subsequently [ˈsʌb.sɪ.kwənt]; manufacturer [ˌmænjuˈfæktʃərə(r)]; component [kəmˈpəʊ.nənt]; vehicle [ˈviːəkl]; aluminium [ˌæl.jəˈmɪn.i.əm]; uranium [jʊˈreɪ.ni.əm]; zirconium [zɜːˈkəʊnjəm]; beryllium [bəˈrɪl.i.əm]; niobium [naɪˈəʊbɪəm]; silicon [ˈsɪl.ɪ.kən]; germanium [dʒəˈmeɪ.ni.əm].

Text

The British Steel Industry Today

Most of the early developments in iron and steel production originated in Britain, the world’s eighth largest steel-production nation in 1979. The Iron and Steel Act 1967 brought together into public ownership 14 major companies and created the British Steel Corporation (BSC). In recent years BSC has produced about 82 per cent of Britain’s crude steel and is the largest steel undertaking in Western Europe. As a result of the widespread industrial recession, employment in the steel industry has been declining, both in Britain and in other countries.

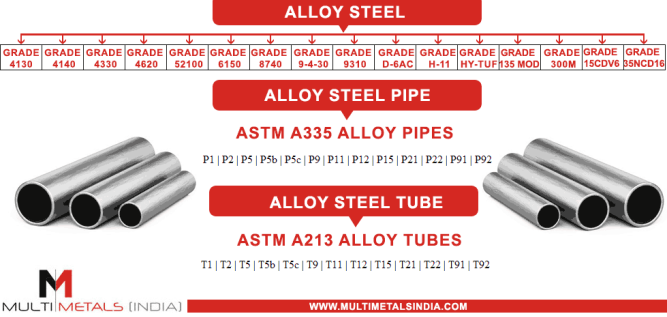

The remaining (private sector) companies are represented by the British Independent Steel Producers’ Association whose members employ some 60,000 people and account for over a third of the value of the industry’s turnover. The private sector is particularly strong in the manufacture of alloy and stainless steels and of finished products for the engineering industry. The main steel producing areas are Yorkshire and Humberside (32 per cent of crude steel output in 1979), Wales (32 per cent), the Northern region (15 per cent), Scotland (8 per cent) and the West Midlands (5 per cent).

The remaining (private sector) companies are represented by the British Independent Steel Producers’ Association whose members employ some 60,000 people and account for over a third of the value of the industry’s turnover. The private sector is particularly strong in the manufacture of alloy and stainless steels and of finished products for the engineering industry. The main steel producing areas are Yorkshire and Humberside (32 per cent of crude steel output in 1979), Wales (32 per cent), the Northern region (15 per cent), Scotland (8 per cent) and the West Midlands (5 per cent).

About 75 per cent of British steel producers’ deliveries of finished steel products are used by home industry and the remainder for direct export, the major markets for which are the rest of the European Community and the United States. A large part of the steel used by industry in Britain is also subsequently exported as part of other finished products.

The castings industry plays an important role in meeting the needs of manufacturers for essential components for products sold both in Britain and abroad. Its main customers are the vehicle, mechanical engineering, building and construction industries. The British Cast Iron Research Association, the Steel Casting Research and Trade Association conduct much of the research and development in the industry.

Britain’s non-ferrous metal processing and fabricating industry is one of the largest in Europe. Its major products are aluminium (both virgin and secondary metal), secondary and refined copper, lead and primary zinc. Tin mining in Cornwall supplies about 25 per cent of Britain’s tin requirements but otherwise British metal smelting and refining industries are based on imported ores. Britain is also a major producer of the newer specialised metals including uranium, zirconium and beryllium for the nuclear energy industry, niobium for aircraft production and selenium, silicon, germanium and tantalum for electronic apparatus. Titanium and titanium alloys are also produced and used in aircraft production, power generation and North Sea oil production, where their lightness, resistance to stress, flexibility and resistance to oxidisation are especially valued. Nearly half the industry is situated in the Midlands. Other centres include south Wales, London, Tyneside and Avonmouth, where a zinc smelter of some 100,000 tonnes capacity operates. Three large-scale aluminium smelters provide 85 per cent of Britain’s requirements for primary aluminium. The large non-ferrous metals fabricating industry uses large quantities of imported refined metals such as copper, lead, zinc and aluminium. A wide range of semi-manufactures is produced in these metals and their alloys, and, particularly in aluminium, firms are engaged in smelting, casting and fabrication by rolling, extrusion and drawing; advanced techniques of powder metallurgy and pressure die-casting are also employed. In recent years considerable progress has been made in the development of ‘superplastic’ alloys, which are more ductile and elastic than conventional alloys.

Scientific and technological research for the industry is conducted by the Warren Spring Laboratory of the Department of Industry and by the British Non-Ferrous (BNF) Metals Technology Centre.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word- combinations given below. Use them in the sentences of your own.

Необроблена сталь; об'єднати; підприємство; спад виробництва; приватний сектор; зайнятість (робочої сили); випуск сталі; кінцевий продукт; машинобудування; ливарне виробництво; виробник; очищена мідь; видобуток олова; літакобудування; ударостійкість; потужністю в 100 тон; прокатка; гаряче штампування; прогресивні технології; порошкова металургія; оборот.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. to be represented

2. alloy

3. stainless steel

4.deliveries of finished steel products

5.to play an important role/part in

6. to meet the needs of

manufaсtureres

7. essential components

8. virgin metal

9. secondary metal

10. resistance to oxidation

11. smelting industry

12. refining industry

13. processing industry

14. superelastic alloys

15. conventional alloys

16. semi-manufacture

1. обробна промисловість

2. сплав

3. звичайні (традиційні) сплави

4. стійкість до окислення

5.сталеплавильна промисловість

6. необроблений метал

7. напівфабрикат

8. поставки кінцевих продуктів сталеливарного виробництва

9. вторинний (оброблений) метал

10. основні компоненти

11. відігравати важливу роль

12. наделастичні сплави

13. задовольняти потреби

виробників

14. бути представленим

15. афінажна промисловість

16. нержавіюча сталь

Exercise 3. Answer the following questions.

1. What was the purpose of the Iron and Steel Act? 2. What organization represents the private sector in British metallurgy? 3. Where are the finished products of steel industry used? 4. Why is the castings industry so important? 5. Does non-ferrous metal processing play an important part in British metallurgy?

Exercise 4. Agree or disagree with the following statements.

1. The private sector of British metallurgy is not particularly strong.

2. Britain uses all its steel producers deliveries of finished steel products only for the needs of home industry.

3. The castings industry is underdeveloped in Great Britain.

4. Britain’s non-ferrous metal processing and fabricating industry is one of the largest in Europe.

5. Nearly half of the industry is situated in the Midlands.

6. Britain does not produce the newer specialised metals (uranium, beryllium, etc.)

Exercise 5. Circle the letter of the answer that best matches the meaning of the underlined word.

1. The Iron and Steel Act 1967 brought together into public ownership 14 major steel companies.

a) united b) disintegrated

2. The major steel producing areas in England are Yorkshire and Humberside.

a) minor b) main

3. This institute conducts much of the research in the industry.

a) fulfils b) carries out

4. All these qualities are highly valued.

a) appreciated b) demanded

5. About 75 per cent of steel products are used by home industry.

a) domestic b) foreign

6. The private sector is very strong in the manufacture of stainless steel.

a) processing b) production

7. Advanced techniques are highly employed in modern industry.

a) used b) applied

8. I think this is the most advanced method in language-learning.

a) modern b) progressive

Exercise 6. Give a written translation of the following passage.

The output of non-ferrous metals and their alloys in 1993 included primary and secondary (recycled) aluminium and copper, as well as aluminium and copper and copper alloy semi-manufactures. The production of metal relies mainly on imported ores and recycled material of both domestic and overseas origin.

The output of non-ferrous metals and their alloys in 1993 included primary and secondary (recycled) aluminium and copper, as well as aluminium and copper and copper alloy semi-manufactures. The production of metal relies mainly on imported ores and recycled material of both domestic and overseas origin.

Britain is a major producer of specialized alloys for high-technology requirements in the aerospace, electronic, petrochemical, nuclear and other fuel industries. Aluminium, lithium, developed by British Alcan Aluminium, is ideal for use in aircraft, being lighter, stronger and more rigid than normal aluminium.

There is also an important sector producing copper and copper alloy semi-manufactures for use in a wide variety of products like electric wire and cable; tube and fittings for plumping and valves; components for the engineering and transport industries.

Lesson 9

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Sulphur [ˈsʌl.fər]; sulphide [ˈsʌl.faɪd]; pure [pjʊə(r)]; electrolysis [ɪˌlekˈtrɒl.ə.sɪs]; sulphuric [sʌlˈfjʊərɪk]; cathode [ˈkæθ.əʊd]; anode [ˈæn.əʊd]; galena [gəˈliːnə]; corrosive [kəˈrəʊ.sɪv]; considerate [kənˈsɪd.ər.ət]; pewter [ˈpjuː.tər]; aqueduct [ˈæk.wɪ.dʌkt].

Text

The First Non - Ferrous Metals

Non-ferrous metals are the metals not composed of or containing iron. As it has been said before, copper was one of the first metals to be used. In its natural form, copper occurs in the ground as copper ore, a mineral. But this ore contains only 0.5 - 1 per cent of the metal. The rest is rock. The world produces 9.6 million tonnes of copper a year. This means that more than a thousand million tonnes of ore have to be removed from the ground and the pure copper extracted.

Most copper is extracted from a compound of iron, sulphur, and copper called sulphide ore. Hot air is blown into a furnace to separate the copper from the iron and sulphur. The iron and sulphur react with the oxygen to form iron oxide and sulphur dioxide, leaving molten copper metal. This copper, known as blister copper, is about 98 per cent pure. A process called electrolysis is needed to separate the remaining impurities. During this process a slab of blister copper is suspended in a solution of copper sulphate and sulphuric acid, where it acts as a positive electrode (anode). When electricity is passed through the solution, the copper in the anode is dissolved. The pure copper collects at the negative electrode (cathode) and the impurities fall below.

Copper is a good conductor of heat and electricity. We use it to make cooling utensils and all sorts of pipes for carrying hot water, both in homes and in industry. We also use it to make different kinds of electrical devices, such as lightning conductors and the electric coils in motors. Copper does not rust easily, so it lasts a very long time.

Such metals as lead and tin were widely known in Roman times. Lead is a soft malleable, ductile, bluish-white, dense metallic element, extracted chiefly from galena and used in containers and pipes for corrosives, in solder and type metal, bullets, radiation shielding, paints and anti-knock compounds.

Some Roman aqueducts still stand today because they were lined with lead and lead does not rust. Many thousands of tones were used in a single aqueduct. So much lead was used in water-supply systems that eventually the Romans suffered some lead-poisoning.

Tin was the fifth metal discovered by man. It is a malleable, silvery metallic element obtained chiefly from cassiterite. It is used to coat other metals to prevent corrosion, and forms part of numerous alloys such as soft solder, pewter, type metal and bronze. For example, pewter, an alloy of lead and tin, was widely used in Roman times to make cups and dishes.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word-combinations given below. Use them in the sentences of your own.

Кольорові метали; містити залізо; витягувати; залізо і сірка вступають в реакцію з киснем; електроліз; сляб; анод і катод; електрообмотка; блискавковідвід; галенит; припій; гарт; каситерит; запобігання корозії слід передбачити; м'який припой; сплав на олов'яній основі; олово; система водопостачання; іржавіти; акведук.

Exercise 2. Match the English words and word combinations given below with their Ukrainian equivalents.

1. to be composed of 1. їдка речовина

2. sulphide ore 2. осідати на дно

3. sulphur dioxide 3. складатися з

4. blister copper 4. тривати довгий час (довготривалий)

5. fall below 5. електроприлади

6. electrical devices 6. двоокис сірки, сірчистий ангідрид

7. to last a long time 7. протирадіаційний екран

8. corrosive 8. свинцеві отруєння

9. radiation shielding 9. покривати метали

10. lead-poisoning 10. пухирчаста мідь

11. to cover metals 11. сірчаний (залізний) колчедан, пірит

Exercise 3. Answer the following questions.

1. What is a non- ferrous metal? 2. What is most copper extracted from? 3. Why is copper so widely valued? 4. Were lead and tin widely known in Roman times? 5. How did the Romans use lead? 6. What are the properties of tin? 7. Why is tin widely used for coating other metals?

Exercise 4. Vocabulary in context: Choose the word that best matches the meaning of the underlined word as it is used in each of the sentences.

1. Calcium is obtained from the electrolysis of calcium chloride.

a) destroyed b) got

2. The initial research was not successful, so a second experiment was planned.

a) last b) first

3. He wanted to shield himself from the burning sun.

a) open b) protect

4. The space between the earth and the moon is a vacuum.

a) empty b) full

5. The earth absorbs the water from the rain.

a) gives off b) drinks in

6. All efforts were concentrated on the research programme.

a) devoted b) centered

7. Our natural resources are not inexhaustible.

a) limited b) endless

Exercise 5. Give a written translation of the following passages

Carrie Everson

Carrie Everson

Ores contain a mixture of valuable metallic substance and worthless rock. An American schoolteacher, Carrie Everson, invented a way of separating the two in 1886. She ground up ore and mixed it with oil and acid. This produced a froth in which the metallic substances floated while the rocky materials sank.

Leaching

In some ores the copper is combined with oxygen. In a process called leaching, sulphuric acid is sprayed over these copper oxide ores, which dissolves the copper but not the rock. The copper and sulphuric acid form solution of copper sulphate, which is purified by electrolysis.

Lesson 10

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Criticize [ˈkrɪtɪsaɪz]; achievements [əˈtʃiːv.mənt]; conquistadors [kɒnˈkwɪs.tə.dɔːr]; conquer [ˈkɒŋ.kər]; platinum [ˈplæt.ɪ.nəm]; Chile [ˈʧɪlɪ]; Bolivia [bəˈlɪvɪə]; Mexico [ˈmeksɪkəʊ].

Text

Precious Metals

Why are some metals so much more valuable than others? Gold, silver and platinum have been highly valued for centuries because of their scarsity, beauty and high qualities. The result of the rush for these metals was death, blood and tragedy.

When Christopher Columbus discovered the Americas in 1492, Spanish expeditions soon followed, and though they are much criticised for their cruelty, greed and treachery, the military achievements of the ‘Conquistadores’ were remarkable. First they conquered Mexico and took away its valuable treasures. Seeking more land and wealth they invaded Peru, home of the Incas. Here they murdered the king and stole his vast hoard of gold - probably the greatest in the world. The natives were enslaved and set to work to win more gold. Later the Spanish conquered Chile and Bolivia, both of these countries being rich in precious metals, particularly silver.

To the metallurgists, the most exciting discovery made by the Spaniards was the finding of platinum in the silver mines of Mexico. At that time the new metal was regarded as more of a nuisance than of value. It could not be melted by any known method, though it was possible to make a very realistic imitation gold from it. Later it joined the group of precious metals and is now used for jewelry and in industry. Its high melting point makes it suitable for electrical contacts where the heat of sparks would melt other metals. In the chemical industries its resistance to corrosion is of great value.

To the metallurgists, the most exciting discovery made by the Spaniards was the finding of platinum in the silver mines of Mexico. At that time the new metal was regarded as more of a nuisance than of value. It could not be melted by any known method, though it was possible to make a very realistic imitation gold from it. Later it joined the group of precious metals and is now used for jewelry and in industry. Its high melting point makes it suitable for electrical contacts where the heat of sparks would melt other metals. In the chemical industries its resistance to corrosion is of great value.

Gold is the most malleable of all the metals. It can be hammered into sheets so thin that 250 of them would equal the thickness of a sheet of paper. It is also the most ductile metal. One gram of gold can be drawn into a wire 1.8 miles in length.

Gold is the least chemically active of all metals and does not combine with oxygen to form rust. This ability to resist corrosion makes it very durable, i.e. it may last for centuries. Pure gold is too soft to be used in jewelry so it is usually alloyed with other metals. The proportion of gold in an alloy is measured in karats. Pure gold is 24 karats. A 14 karat gold ring is an alloy of about 58% of gold and small percentages of copper and silver.

Silver is similar to gold in many ways. Like gold, it is very malleable and ductile and so it is also used for jewelry. Silver differs from gold in that it is more reactive and tarnished when exposed to the traces of sulfur in the air. (Silver sulfide, a black deposit, forms on its surface). Pure silver is too soft and so it is usually alloyed with copper to increase its hardness and durability. Sterling silver is 92.5 percent silver and 7.5 percent copper. Silver is used for coins and for photographic film because certain compounds of silver, such as silver bromide, reflect light. Silver is the best conductor of electricity known.

Lexical Exercises

Exercise 1. Find the English equivalents for the words and word-combinations given below. Use them in the sentences of your own.

Величезний запас золота; взятися за роботу; розглядати; імітація золота; відомий метод; дорогоцінні метали; висока точка плавлення; хімічна промисловість; ювелірна прикраса; вимірювати; втрачати блиск (окислюватися); срібло вищої проби; фотоплівка; срібні копальні.

Exercise 2. Match the English words and word-combinations given below with their Ukrainian equivalents.

1. to critisize for 1. в пошуках нових земель і багатства

2. remarkable achievements 2. підвищити зносостійкість

3. seeking more land and wealth 3. багатий дорогоцінними металами

4. to set to work 4. розтягнути в дріт

5. to equal smth 5. відбивати світло

6. to increase durability 6. взятися зa роботу

7. to reflect light 7. бути рівним

8. rich in precious metals 8. найменш хімічно активний метал

9. the least chemically active metal 9. дивовижні досягнення

10. to draw into a wire 10. критикувати за

Exercise 3. Answer the following questions:

1. What are the precious metals valued for? 2. When did the Spanish expeditions set fot South America? 3. What did they find there? 4. What was their most exciting discovery? 5. Why is it easy to hammer gold into thin sheets? 6. Where is gold used? 7. What are the properties of silver?

Exercise 4. In the text given above you could find the fragments of the

definitions of gold and silver. Make them complete definitions.

Listed in the box are some guidelines for writing good definitions.

They are followed by poorly written definitions. Say, what is wrong

with them and correct them.

1. Identify the class. You may also use descriptions, comparions, examples.

2. Be precise. Do not only identify the class, but give the characteristics that differentiate this object or phenomenon from others.

3. Use negative definitions (like “An apple is not a vegetable”) when you think people have a wrong idea. But then follow it with a proper definition.

4. Be objective. Always remember about those you are speaking to. A child needs an easier and more detailed definition.

1. An apple is round, red and about the size of a fist.

2. An astronomer is a scientist.

3. Radium is an element.

4. A pizza is something really good to eat.

5. Helium is light.

6. Barometer measures air pressure.

7. Conduction transfers heat.

8. An agronomist is a person who practices agronomy.

Exercise 5. Give a written Ukrainian translation of the following passages.

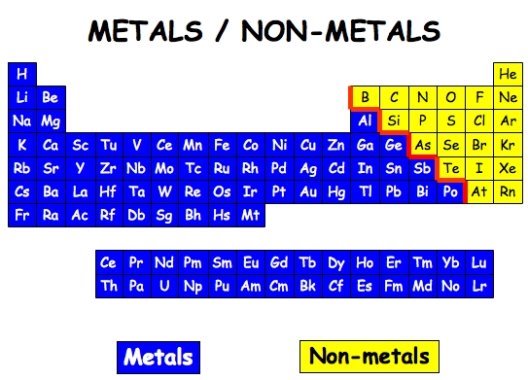

Metals and Non-metals

The 105 elements do not, fortunately, exhibit 105 completely different sets of properties. When the major properties are considered it is found that the elements fall into one or two groups, the metals or the non-metals. The contrast between the properties of these two groups is given below. It is not to be expected that all elements in one class will agree in every detail; some differ in one or two properties from the others of their class; these exceptions are indicated in brackets.

Metals Non-Metals

Physical properties

1.Solid at room temperature (mercury 1.Many are liquids and gases at room

is the only liquid metal) temperature

2.Have a high density (except 2. Density is usually low

potassium and sodium)

3.Can be moulded by pressure, i.e. 3. Solid non-metals are brittle

they are malleable

4.Have high melting points and 4. Have low melting points and

boiling points boiling points

5.Are good conductors of heat, 5. Are poor conductors of heat and

electricity electricity (graphite is the only good

conductor of electricity among non-

metals

6.Can be drawn into wire, i.e. they 6.Cannot be drawn into a wire

are ductile

Chemical properties

7. Have basic oxides 7. Have acidic oxides

8. React with dilute acids form- 8. Salts of non-metals do not exist

ing salts

9.Form positive ions 9. Form negative ions

10.Are liberated at the cathode 10. Are liberated at the anode

during electrolysis (hydrogen during electrolysis

acts as a metal)

The chemical properties are much more conclusive than the physical properties for deciding whether a particular element is to be regarded as a metal or a non-metal, e.g. if an element forms a basic oxide it must be classified as a metal. A basic oxide is never formed by a non-metal.

Lesson 11

Phonetic Exercise

Practise after the speaker and learn to pronounce the words given below:

Elaborate [ɪˈlæb.ər.ət]; alchemist [ˈæl.kə.mi]; purifying [ˈpjʊə.rɪ.faɪ]; dishonest [dɪsˈɒnɪst]; credulous [ˈkred.jʊ.ləs]; admirable [ˈæd.mɪ.rə.bl̩]; encyclopedias [ɪnˌsaɪ.kləˈpiː.di.ə]; philosopher [fɪˈlɒs.ə.fər]; disease [dɪˈziːz]; laboratory [ləˈbɒrətri]; monograph [ˈmɒn.ə.ɡrɑːf].

Text

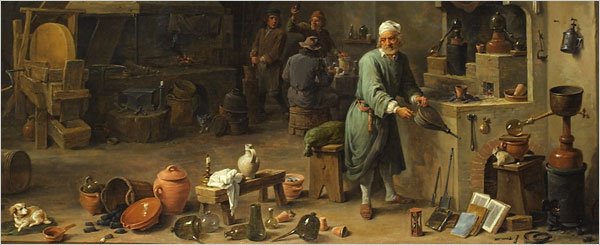

The Alchemists

During the Middle Ages, alchemists searched for a way to change base metals, like lead, into gold. They thought that if they could find the right formula, they could, for example, add a certain amount of mercury to lead and produce gold. Even the great Sir Isaac Newton believed it could be done.

The experiments the alchemists carried out were sometimes very elaborate. Some put the metals through a hundred purifying processes and added a great deal of so-called magic as well. Of course, all these efforts came to nothing, but the alchemists were convinced that they would succeed and plodded on until about the seventeenth century.