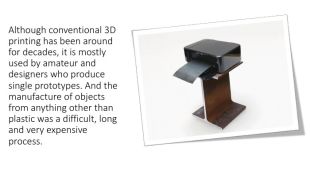

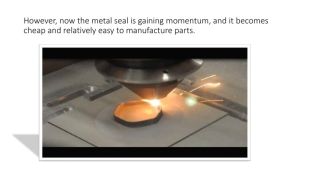

3d printing. цікава призентація про новітню розробку

Про матеріал

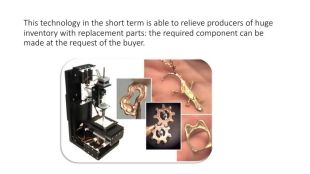

цікава призентація про 3d принтер англійською мовою. Стане в нагоді студентам та вчителям англійської мови Перегляд файлу

Зміст слайдів

Безкоштовний сертифікат

про публікацію авторської розробки

про публікацію авторської розробки

Щоб отримати, додайте розробку

Додати розробку